The first mixer-blender was patented during the late 1800s in Maryland, USA as a home utensil. To the public, it proved to be revolutionary. It was only a matter of time until the home-based version was redesigned for industrial purposes and by the start of the 20th century, an Ohio based engineering firm invented the first industrial mixer-blender.

We’ll discuss the basics surrounding how a mixer-blender actually works, some tips and tricks to keep in mind when it comes to the purchase and operational process, and what to look for when searching for Used Industrial Mixers & Blenders for Sale.

Most Popular Types of Mixer-Blenders

Some of the most popular types of Mixer-Blenders found on Surplus Record include: Ribbon Mixer-Blenders, Liquefier Mixer-Blenders, Twin Shell (V-Type) Mixer-Blenders, Planetary Mixer-Blenders, and Paddle Mixer-Blenders. Each of these mixers serves as practical pieces of equipment across a range of industries, catering to specific mixing needs with their unique functionalities. Let’s delve into how they function and the key roles that each individual mixer-blender plays within various sectors.

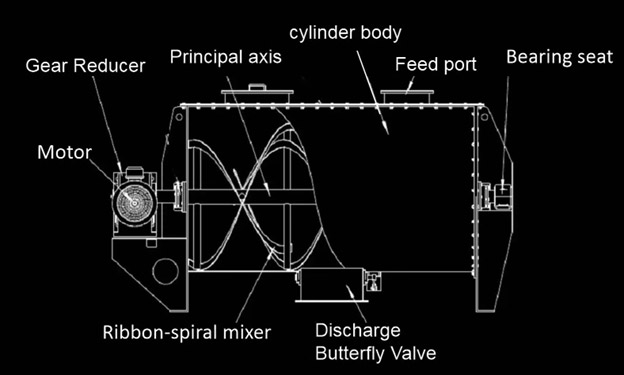

The Ribbon Mixer-Blender

One of the most versatile mixers on this list is the Ribbon Mixer-Blender. These mixers are often made of stainless steel and are used mainly for food and chemical processing, thus the stainless steel body. They consist of a U-shaped horizontal bucket which houses a steel rotating shaft (the ribbon). This ribbon acts as the main agitator for the mixing process. When the mixer is in operation the ribbon rotates at approximately 300fpm (although this varies) and the product inside is mixed to great effect.

Ribbon mixers are highly popular for many reasons. They are arguably the most productive of all the industrial mixers listed, with workloads generally completed within 20 minutes. This speed proves to be a useful asset throughout production based industries. The mixing capabilities of the Ribbon Mixer are broad, they can mix a range of materials thoroughly due to the countercurrent movement and triple action mixing of the ribbon. Maximum capacity is only limited by the size of the machine itself and there is a wide variety of sizes available on the market to suit. The Ribbon Mixer is the go-to mixer for most standard industrial mixing procedures. View our available range of used ribbon mixers for sale.

The Liquefier Mixer-Blender

A more specialized piece of equipment can be found in the Liquefier Mixer. These are specifically used in the processing of food products with the general purpose of combining solids/liquids and agitation. A Liquefier functions similar to that of a home mixer/blender used for baking. It consists of a large steel bowl which is based below 2 (or more) steel mixers. These mixers are the agitator and when the machine is in use, these agitators enter the bowl and mixing commences. Due to the specific safety requirements needed of this mixer, the initial stainless steel fabrication of the mixer and the machine’s maintenance post fabrication, create an efficient and safe product to use for the mixing of food. Mixing can be achieved upon materials with a variety of different consistencies, whether they be sticky, oily or solid. This is even more effective when the mixer has wipers within the bowl which clear away trapped product on the internal wall of the bowl. Have a look through our available range of used liquefier mixers for sale.

The Twin Shell Mixer-Blender (V-Type)

Twin Shell Mixers are designed to mix solids to liquids, most commonly within chemical based industries. Centrally based is an V-shaped shell which is where the mixing occurs. The material to be mixed is placed inside the shell which then rotates continuously. As the shell rotates, the material inside accelerates back and forth and on impact the material is broken down as required. The V-shape of the Twin Shell Mixer proves to be a great advantage to the mixing process. When the material makes contact with the internal point of the V, the disintegration of the material at hand is much more efficient than if it was simply mixed mechanically. Our available range of used v-type mixers for sale can be viewed here.

The Planetary Mixer-Blenders

The Planetary Mixer is most famously used within industrial bakeries for pastry mixing. Functionality is similar to the Liquefier blender; a steel bowl is based below mechanically driven agitators which are lowered into the mix and rotate at high speed to achieve agitation. The modernity of this mixer is often quite advanced due to its connection to the pastry industry which requires specific and specialized movements; many models have control panels which are designed for greater control of mixing. Maintenance tends to be low, sizes available are quite limitless and most of all, mixing is extremely efficient and uniform due to the mixers design specifications. Have a look through our available range of used planetary mixers for sale here.

The Paddle-Mixer Blender

The Paddle Mixer-Blender is revered for its robustness and adaptability, making it a staple in various industrial applications. It features large, paddle-shaped agitators that deliver an aggressive mixing action, ideal for handling heavy or dense materials. This mixer excels in both wet and dry scenarios, adept at incorporating liquids into powdery substances with unparalleled efficiency.

Predominantly used in sectors like construction for mixing dry mortar, and in animal feed production, its design ensures a thorough and uniform mix in a fraction of the usual time. The paddle mixer’s versatility is further highlighted by its ability to adjust to different mixing conditions, making it a preferred choice for challenging mixing tasks. Its reliability and performance in creating homogenous mixtures solidify its position as an essential piece of equipment in a wide array of industrial processes. Take a look at the used paddle-mixers we currently have for sale.

Uses and Applications

In many industries, mixing is often the first step in the making of products. Mixers-blenders can be found being used for the effective combination of substances and materials within: chemical, agricultural, pharmaceutical, plastics, food processing and mineral industries.

The use of mixers throughout these industries is generally intensive and production based, meaning that mixer-blender design is based around its continuous and regular utilization. Mixers will be found as crucial piece equipment in the combining of substances to produce well known products such as: toothpaste, hair and beauty products, vitamins, milk and dairy products, biodiesel, cement, medicines and more.

Can I use a paddle mixer with a drill?

Yes, a paddle mixer attachment can be used with a power drill for smaller or medium-sized mixing tasks. This setup is ideal for home projects or light industrial applications where a dedicated paddle mixer isn’t available. Ensure the drill can handle the viscosity of the materials to avoid overstraining the motor.

Can I use a paddle mixer for concrete?

Absolutely. Paddle mixers are well-suited for mixing concrete, especially for small to medium batches. Their design allows for a thorough mix, ensuring that the concrete is evenly blended before pouring. It’s crucial to select a mixer with the appropriate size and power for the volume of concrete you plan to mix.

Can you mix screed with a paddle mixer?

Yes, paddle mixers are effective for mixing screed, providing a consistent and lump-free mixture. They are particularly useful for achieving the desired texture and homogeneity needed for flooring applications. As with concrete, choosing a mixer that matches the screed volume and consistency is key to efficient mixing.

What to Look for When Buying a Mixer-Blender?

Now that you understand the general differences between Ribbon, Liquefier, Twin Shell and Planetary Mixer-Blenders you may be asking yourself, what do I need to be aware of when looking to buy a used mixer? Use the following pointers for reference:

Power Capabilities

The power options available for each type and model of mixer will be different. Know what you will be mixing and ask your mixer-blender professional for advice as to which mixer would be more suitable for your task. A mixer which is too powerful will expend too much power and cost you money, while a mixer which is lacking power will struggle to complete the job.

Size and Capacity

Size and capacity are crucial considerations that directly influence the mixer’s efficiency and compatibility with your processing needs. Typically, mixers are designed to operate effectively at around 65% of their total capacity, providing optimal mixing without the risk of overflow or underperformance. This guideline is especially pertinent for Paddle Mixer-Blenders, known for their robust mixing action and ability to handle a wide range of materials.

It’s advisable to choose a mixer with a slightly larger capacity than your estimated requirement. This ensures not only that your materials are mixed efficiently but also accommodates any future increases in production volume without the need for immediate equipment upgrades. Assessing the volume of material you plan to mix and understanding the maximum and minimum batch sizes that the mixer can handle will guide you in selecting a size and capacity that aligns with your operational demands.

Mixer Base Material

We mention this because for some, this could be easily overlooked. The material in which the mixer is made from is extremely important in your decision of which mixer to purchase. For example, you would never use a mild steel based mixer to combine food products, the food would become inedible, instead a stainless mixer would be utilized due to its cleanliness.

Determine Your Specs

It is important to understand and determine the square footage/size, and horsepower specifications of the specific piece of equipment you need. All of Surplus Record’s listings of Mixers-Blenders are listed in order from lowest to highest in terms of horsepower capabilities.

Useful Accessories

Modern mixer-blenders will have many unique accessories available to purchase. The purchase of accessories can potentially improve productivity and economy! Below are some recommended accessories:

- Safety Guards: mixer-blenders will have an open top depending on the model. By investing in a good guard, you can not only help to contain your specific substance better but also improve the health and safety of operation.

- Spatulas or Scrapers: due to the nature of mixing, it is only natural that the product will get stuck to the side of the mixing surface and mechanical components. Purchasing a specialized spatula/scraper helps to make for an easier clean up.

- Thermometer: can be crucial when mixing important food or chemical products to maintain consistency or quality.

- Lighting equipment: the inside of a mixer can be dark, making viewing difficult. By attaching an external industrial light to the mixer or a nearby surface viewing your batch will become easy.

Surplus Record: Tips and Tricks

When searching for used industrial mixers & blenders for sale on our platform, we have attached some of our best tips and tricks to make the entire process a breeze.

- Make use of our Location Settings: At the top of the page, when on the list for your desired piece of equipment/machinery, enter your desired location and you’ll be taken directly to what we have available in your area.

- Looking for an Auction?: On the listing page, select the blue checkbox on your right which says “Auction” and you’ll be taken to our available products for sale that are on auction.

- On a Budget?: Select the toggle “Sort by Relevance” and then click “Price low to high” to view our cheapest to most expensive products for sale.

- Don’t forget the Search Bar: Already know what you are looking for? Utilize our search tab at the top of your page to find specific listings out of hundreds available.

Quick Access: Mixer-Blender Dealers

- Federal Equipment Co. | Ohio

- Frain Industries | Illinois

- Perry Videx | New Jersey

- Arnold Equipment | Ohio

At Surplus Record, we understand that the process of searching for the best used mixer or blender for sale can be quite daunting. Our advice is to take your time, do your research and use this buying guide and the process of finding the best mixer-blender to buy will be straightforward. Almost easy!

Quick Access: Mixer-Blender Manufacturers

The top manufactures available on Surplus Record for used Mixer/Blenders include:

Ribbon Mixers

Liquefier Mixer

Twin Shell Mixer

Planetary Mixer

Need more help or information about Mixer-Blenders? Still can’t find what you’re looking for or need more advice from a professional dealer? Head on over to the “Wanteds” section of our website and select “Buy” at the top and “Processing Equipment” for the industry. Fill out the form and a dealer that specializes in Mixer-Blender machinery will get back to you ASAP. It’s free to do, and our dealers are happy to help out!