Over time, the variety of types of hydraulic presses has expanded and selecting the appropriate hydraulic press may have become more challenging as a result. The good news is, we’ve outlined below the key features you need to look out for when considering purchasing a hydraulic press.

What to Consider when Choosing a Hydraulic Press

There are a host of factors that should be put into consideration when thinking about getting a hydraulic press. The size and complexity of your job, along with your physical space are just some of the factors that will help inform which hydraulic press is best for you.

We recommend on making a summary of jobs you want the press to engage in; which can shine a little light on the kind of strength, the size, the type you will need, the model required, and so on. Ensure you understand the level of work you can put on the hydraulic press. The best hydraulic press can bend, form, mold, stamp, punch, and shape objects.

Tonnage – Tonnage represents the amount of power required for using the hydraulic press. Tonnage will typically range from as small as 1 ton, to over 5,000 and even 7,000 tons of force! But it can still go higher, in fact, the largest hydraulic press in the world has 50,000 tons of force! You may not require a lot of tonnage if you’re coming from the use of a mechanical press. However, for any activity you will be performing with the hydraulic press, you typically want the highest tonnage available. This required tonnage is a function of factors, such as material strength, material size, and thickness. You can easily search our site for a press with your required tonnage, for example, type “100 ton” into the search bar within the hydraulic category page and you’ll be presented with a variety of available presses that are 100 tons of force.

- Machine Action – The machine action may differ slightly depending on the kind of hydraulic press. However, generally speaking hydraulic pressing works by compressing a plate against a particular workpiece.

- Press Selection Type – Your specific job and the tonnage needed to achieve it will help you determine the best press type. Not all presses are equal and the range of activities that you can engage in depends on the press you plan to purchase. The C-Frame (also referred to as a “gap frame press”) and H-Frame hydraulic presses are quite common due to their versatility with multiple tasks. The C-Frame presses are typically best suited for applications needing smaller bed sizes and lower tonnages, like assembly. While H-frame presses are large floor units that combine a steel frame, a press cylinder, a pump and a movable bolster—forming an “H” shape and are typically used in repair maintenance facilities and on production lines.

- Accessories – Hydraulic presses may come with a variety of accessories. Examples include automatic cycling, dwell timers, light curtains, limit switches and more. Notwithstanding, a few presses come outfitted with a wide assortment of extra controls that can significantly enhance their usefulness and selecting a hydraulic press with more bells and whistles may wind up saving you some money and time in the long run. That said, it’s always best to gauge your specific needs and usage before investing in a new machine.

- Quality – While you may want a rudimentary hydraulic press for smaller tasks, bear in mind there is a 10-ton hydraulic cylinder H that is capable of harder metalworking tasks. It’s always best to check your equipment for rigidity, speed, power, length, and size, etc. before taking on a job.

- Speed – Currently, there are few hydraulic presses that give you the same speed you get out of mechanical presses. If you’re aiming to work quickly on a fixed application with a short feed stroke, using the mechanical press is typically the better option. However, newer hydraulic presses can do a great job without requiring too much effort to set up. You don’t need to stress over setting things like stroke or tracking down onto the specific spot where the greatest tonnage hits.

- Stroke depth – The depth of the stroke may not be more than 0.020″ if you determine the bottom using a limit switch. Numerous presses can be set to switch at a user-selected pressure, which generally brings about uniform parts. However, you must use “kiss” blocks for a high degree of stroke depth precision.

- Automatic feeding equipment – When feeding objects into the press, the hydraulic presses need a feeder, which is powered separately and connected to the hydraulic press’ control panel. The automatic feeding equipment allows you to get all objects in place at the right time. There are numerous types of feeding systems available, including air feeds, roll feeds, and hitch feeds.

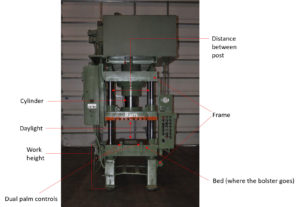

Parts of a Hydraulic Press

Hydraulic presses are machines that work by compressing a plate against a workpiece. Hydraulic presses are a core piece of machinery in fabrication plans and used in a variety of industries. The machines experience improvement along with technological advances, including faster machining times, improvements in seals, lower maintenance, and the introduction of programmable logic controls and other electronically-based programming. A hydraulic press machine consists of the following parts:

- Frame: This is the primary structure and it features cylinders as well as the working surface.

- Cylinders: These are a combination of ram, seals, packing, and the cylinder itself. They are jointly responsible for determining the hydraulic press tonnage.

- Bed: This is a flat, fixed surface that provides support.

- Bolster: This is a plate or structure mounted to the bed. Many manufacturers provide a removable bolster.

- Stroke Control: Stroke control allows you to determine the length of each stroke, based on the features of the press cylinder. It can also be adjusted in multiple ways, including: top of stroke, pre-slowdown point, and bottom of stroke.

- Throat Clearance: This extends from the middle of the ram to the back of the bed and represents diameter.

- Daylight: It represents the highest press capacity and extends from the bolster to the position below the ram.

- Work Height: Work height measures the distance that extends from the bolster peak to the floor.

- Dual Palm Button Controls: This is used for activating the hydraulic press. The control contains two buttons that must be pressed simultaneously, usually with both hands.

Popular Types of Hydraulic Presses

There are several kinds of hydraulic presses available today. Before purchasing a press, you should understand the differences between the capacity of each kind of hydraulic press and its expected application. A wide scope of industries and businesses utilizes hydraulic presses for different applications, some of which feature distinct features that their production process needs.

- C Frame (aka Gap Frame) – Also known as the gap frame, this popular press type is known for its distinguished frame style. It resembles a C shape, hence the name. The hydraulic floor-to-ceiling C-frame presses give an amazing force that keeps a tight impression and are best for situations requiring more modest bed sizes and lower tonnage.

- H Frame – These are low pressure, lower oil temperature systems meant for higher efficiency and safer operation. Their open sides are also helpful for work on longer pieces of material.

- Straightening – This common style of press applies even pressure in order to straighten/flatten metal.

- Fluid Forming – Also known as bag presses or fluid-cell presses, these are presses that utilize flexible bladders filled with fluid to reshape metal into non-conventional shapes. This happens using pressure as high as 11,600 psi. to reshape adaptable materials into desired shapes.

Electric Press Brakes Vs. Hydraulic Press Brakes

When it comes to selecting a press, two main options include hydraulic presses and electric presses. But what’s the difference between the two, and when should you consider one over the other?

Let’s start by examining hydraulic presses, which have long been considered the standard across multiple industries. This long-running technology has proved itself to be a highly reliable option, and over the years, manufacturers have developed multiple kinds of hydraulic presses. This can range from robotic press brakes and double-servo press brakes to hydraulic torsion shaft brakes and combination electro-hydraulic brakes. Many of these options are also relatively inexpensive.

The older nature of hydraulic press is also part of its downside. Because these presses use oil, any change in temperature will greatly impact the machine’s efficiency. They also require regular maintenance, and the changing and disposal of its oil is an environmental hazard. Finally, one of the most problematic aspects of hydraulic presses is that they must continually run even when not in use. They require less energy to operate, but their “always on” nature means that energy costs could be higher in the long run.

Electric presses don’t have that problem. They only need to be on while actually bending material, and they pose no pollution risk. Maintenance requirements are minimal, too, and with their adjustable bending speeds, high precision, and high efficiency, they can often produce more accurate end products at a faster pace.

However, electric presses also face some significant limitations. They’re subject to a hard tonnage limit with the most advanced machines generally only able to put out 80 tons of bending force. Finally, they’re generally much more expensive and quickly advancing technology, which means you might end up with a pricey piece of equipment that’s quickly outclassed by newer models.

In the end, selecting the right press brake will depend on your end-use case and allotted budget.

What’s your Intended Use and Production Line?

Compiling a list of tasks you’ll want your press to complete, along with the volume, can give you a better understanding of the power, durability, type, and model of hydraulic press you will require. A hydraulic press can truly do a lot of things, including but not limited to: twisting, shaping, deformation, and even stepping.

Overall Quality and Long-term Maintenance Costs

When getting a hydraulic press, you should pay attention to the short and long-term implications. Build quality can play a role in the longevity of a hydraulic press. A press that’s been manufactured using lower quality components and materials may seem like a wise investment short-term, but frequent maintenance and repair costs can add up quickly, ultimately making you wish you had invested in the pricier high-quality alternative in the first place. Whether you’ve chosen a budget-friendly press or the most expensive version available, it’s important to perform routine maintenance on your hydraulic press to keep it running smoothly.

The frequency of use and materials pressed can also take a toll on the life of a press. Minor issues should be addressed as they’re discovered instead of letting problems compound over a long period of time resulting in much more expensive fixes.

Hydraulic Over Mechanical

There have been many comparisons between hydraulic and mechanical presses. While each has its merits, hydraulic presses ultimately come out on top. They tend to be better than their mechanical counterparts because they are more efficient, offer better value for money, and save space.

Other Considerations for a Hydraulic Press

You’ll also need to know how to maintain a hydraulic press. Here are some tips to maintain your press:

- Apply appropriate pressure

- Keep the environment cool

- Regularly check for leaks

- Ensure smooth valve shifts

- Keep the oil clean

- Check the electronics

Pros and Cons of Hydraulic Press

Pros

- They tend to weigh less.

- Reduces subsequent welding and assembly.

- Offers strength and rigidity.

- Reduces mold parts and costs.

- Quiet Operation.

- Lower startup and working costs.

- They are protected compared to a mechanical press.

- Offers a full-force stroke.

Cons

- May have poor functional speed.

- They use moderately high energy.

- Excessive pressure could cause hydraulic lines to burst.

- Treatment of hydraulic fluids can be untidy.

- The framework can become very hot.

- Hydraulic fluids may be flammable.

Real-Life Applications of Hydraulic Press

Hydraulic Presses are extremely flexible and can be utilized in a wide range of industries and businesses. Some of the common ones include:

- Car Part Manufacturing

- Automobile crushing

- Blacksmithing and sword making

- Powder Making/Food Manufacturing Plants

- Aerospace & Military Industry Fabrication

- Electrical and Appliance Manufacturing

Accessories for Hydraulic Press Machine

Hydraulic press machines can come with accessories that greatly improve their usage. These used to be somewhat limited in scope but advancements in technology have allowed more sophisticated features. Some common accessories you may find on a hydraulic press include:

- Touch screens

- Timers

- Die cushions

- Rotating tables

- Sliding bolsters

- Ejecting cylinders

- Distance reversal

- Feedback systems

- Light curtains

- Pressure reversal

- Automatic cycling

Finding Hydraulic Presses on Surplus Record

Once you’ve determined the type of press you or your business needs, finding one on Surplus Record is easy! With our newly redesigned website, searching is a breeze. You can use the search bar in the header of our website to perform a basic search. Simply type in “hydraulic press” or narrow it down by specific press type.

Manufacturers include Wabash, Pacific, Dake, Denison, Williams and more.

We also work with several dealers who specialize in presses of various types. You can also find dealers in your area or by name who specialize in hydraulic presses.