An engine lathe, sometimes referred to as the “father of all machine tools” is a horizontally shaped piece of machinery that is often used to cut or shape material such as metal or wood. The material is quickly turned, and the machine uses special cutting tools to create a specified shape.

Engine lathes are indispensable in engineering facilities and workshops. This is due to their wide range of abilities, including cutting, drilling, and turning, among others. There are many things to consider before purchasing an engine lathe, and since it can prove somewhat challenging, we have prepared this guide to provide you with all the must-know information.

A Brief History of the Engine Lathe

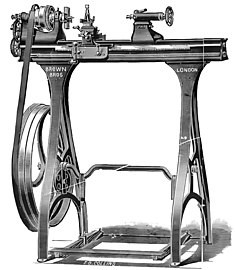

The lathe is actually quite ancient, with its first use dating back as far as 1300 BC in Egypt. Early iterations of the lathe were also used by the Greeks. As you might imagine, the first lathe was rather simplistic. One person would turn the wooden work piece using a rope or string, and another person would shape the spinning work piece using a sharp tool. This design was later improved with the addition of a turning bow, and eventually a foot pedal (much like a sewing machine) to aid in the rotating of the work piece. During the Industrial Revolution, the lathe was an important tool of the era since it helped fabricate other machines.

The lathe is actually quite ancient, with its first use dating back as far as 1300 BC in Egypt. Early iterations of the lathe were also used by the Greeks. As you might imagine, the first lathe was rather simplistic. One person would turn the wooden work piece using a rope or string, and another person would shape the spinning work piece using a sharp tool. This design was later improved with the addition of a turning bow, and eventually a foot pedal (much like a sewing machine) to aid in the rotating of the work piece. During the Industrial Revolution, the lathe was an important tool of the era since it helped fabricate other machines.

By the end of the 1800s, electric motors were the power source of choice for lathes, revolutionizing the industry and further speeding up production. The Industrial Revolution saw the addition of steam- or water-powered engines to lathes, greatly increasing their power and efficiency. These came to be known as engine lathes and became the template for today’s hobbyist, commercial, and industrial lathes. Virtually all lathes are comprised of a bed (which is the machine’s basic frame); a carriage (a part that facilities precise positioning of tools); and the cross-slide (a maneuverable piece that shuttles your preferred tool back and forth). Different lathe models may be spun by an integral engine, a belt drive, or gear boxes.

CNC (i.e., computer numerical control) lathes differ from other kinds of lathes because of the inclusion of software-driven lathe controls. These machines can cut on a different number of axes, which indicates varying levels of functionality, and different number of fixed positions, additional positions allowing for more detailed cutting. Today, there are engine lathes with manual controls as well as CNC lathes that are completely automated.

What is an engine lathe used for?

The lathe is one of the most important and useful machines in any workshop due to its range of uses. We’ve listed some categories where lathes are commonly used below.

Metal Lathes vs Wood Lathes vs Glass Lathes

Boasting of an unrivaled versatility, an engine lathe can perform all sorts of functions, including cutting, drilling, turning, and even sanding on metals, woods, and glass. Any of these materials can be reshaped easily with the help of a lathe. Wood lathes are usually smaller and are designed specifically for wooden components and carpentry applications.

On the other hand, metal lathes are more rigid, require more power to work on metal components, and tend to be larger. Metal lathes can still be used on weaker materials like wood, aluminum, and steel. Similarly, glass lathes can perform a wide range of operations, including glass blowing. Their primary function is to hold and rotate glass tubing during glass fabrication.

Personal Workshop or Modern business workshop

Lathes needn’t be confined to only large-scale workshops where professionals work. Your neighbor may have their very own lathe in his/her garage. Engine lathes are considered one of the best, most versatile tools for a reason. They are used in a variety of workshops and are accessible enough for hobbyists and professionals alike.

Full automation (CNC) vs manual

An engine lathe can either fall into the category of manual or CNC. CNC is short for computer numerical control, and it represents a fully automatic machining process. While CNC lathes come with full automation that allows you to cut or measure with the highest form of consistency and precision, manual lathes are as the name suggests, controlled manually with little to no precision other than the expertise of the operator. You can still get the required accuracy from a manual lathe, but it may take a bit more patience and skill.

Below is a manual lathe on left vs CNC Lathe on right. (Notice the computer controls on the CNC lathe)

What to Know Before Buying?

Once you’ve determined the types of jobs you’ll need your new lathe to perform, and whether you’d like a manual or CNC lathe, there are several other factors that you should consider before purchasing an engine lathe or metal lathe.

Price

Engine lathes are available in a wide range of prices because their capabilities are so varied. Once you’ve determined the type of lathe you need, you can then decide whether you’d prefer a new or pre-owned lathe. The latter typically being much cheaper but may also come with added maintenance costs.

Parts of Engine Lathe

You should know that the various parts of an engine lathe may be different based on type. Ensure the lathe you want to purchase has all the parts and components needed for the type of work you’ll be doing.

One of the most common engine lathe parts include the tool post for creating symmetry on an axis, a chuck for holding everything in place, and a swindle for rotation. Others include the headstock for attachment, tailstock, for drilling, leadscrew for automation, and carriage for holding and movement. The saddle is the mobile large slide, which freely moves left and right along the machine bed, while the feed mechanism is defined as a tool’s distance traveled during one spindle revolution.

Feed Mechanisms for a lathe

A bar feeder or bar feed is an optional piece of support equipment that allows bar stock to be automatically loaded into a CNC lathe, greatly increasing productivity. The bar loader was specially designed for turning machine types with a large distance between the machine cover and spindle end.

Lathe Types

There are several different engine lathe types available, all of which can be found on Surplus Record. Some of the more popular types of lathes are outlined below.

Mechanical

CNC

- CNC lathes and Turning Centers

- Chucker Lathes

- Turret Lathes

- Saddle Turret Lathes

- Metal Spinning Lathes

- Precision and Second Operation Lathes

- Flat-bed Lathes

Belt Pulley vs Variable Control

Like many engine lathe options, the choice between a lathe that uses a belt pulley (or pulleys) and one with variable control speeds will depend on your end-use scenario. But before we discuss that, it’s wise to understand the differences between these two options.

Belt pulley lathes represent an older and more mainstream technology. The lathe may operate at only one speed, or it could have up to five different step ups in RPMs. So while belt pulley systems may technically have some kind of variable speed control, it’s worth noting that they’ll still end up locked into specific RPMs and that many require manual readjustment to shift speeds. The biggest advantage to belt-pulley lathes is that they tend to be more inexpensive, if you’re working with a single kind of material day in and day out, they make a lot of sense.

Unlike belt-pulley systems, which often need users to manually move the belt to change the machine’s speed, variable-control lathes require nothing more than moving a lever or knob to alter their RPMs. Internal gears do the job of shifting the speed on the fly, meaning that variable controls can easily adjust to multiple types of materials. While more expensive than belt pulleys, they can pay for themselves in efficiency.

Torque Range

Whether you choose a belt pulley or a variable control lathe, you will need to consider if its torque range will work with your end-use scenario. Additionally, you should also determine what its starting torque will be when you power on the lathe. Some applications may require higher or lower starting torques that a particular model can provide.

Size of Lathe you need

Choosing the appropriate lathe size depends on the size of materials you plan to use, specifically their length and diameter. The lathe swing measures diameter, while bed length signifies how long of an object it can work on, which is commonly referred to as “centers” which is the maximum distance between the two centers of the piece of material you are working on. The diameter is measured by taking the length from the chuck’s center point to its edge. You must also consider the size of your workshop or space, as engine lathes come in a variety of sizes. Below are two Lathes that can help you understand the sizing better.

13” Swing x 36” Centers Clausing Engine Lathe vs 72” Swing x 315” Centers Shepard-Niles Lathe.

Buying New Engine Lathes vs Used

When considering the purchase of an engine lathe, you will invariably have to decide whether you’d prefer to buy a new machine or a used one. Which option is best? Unfortunately, there’s no easy way to answer that question. Just as you will find a wide range of new lathes with different options, horsepower, automation add-ons, sizing, and speeds, so you’ll discover that used engine lathes come in many different kinds of conditions. Some will require little refurbishing to work well, and others may need substantial tinkering to function acceptably.

With that in mind, purchasing a used engine lathe has a number of advantages. These pieces of industrial equipment have been made for the long haul, and it’s not uncommon for one to continue to function for decades and sometimes last even longer than the company that produced them. Additionally, because many companies prefer computerized numerical control (CNC) lathes, you can often find high-quality used manual engine lathes for a much better price than newer alternatives.

However, buying used lathes may also pose certain challenges. For instance, used lathes may have accumulated a generation’s worth of grit and grime, requiring careful disassembly and meticulous cleaning. They may also have several parts that need repair or outright replacement, and while many venerable brands have continued to produce replacement parts even after the original company has ceased to exist, others haven’t. Buying a used engine lathe isn’t for someone with limited knowledge or technical skill.

Both new and used engine lathes are viable options for most commercial applications. Your choice will depend on the options available to you, the availability of spare parts, your own technical skill, and whether or not you want to refurbish an older machine.

Why Choose an Engine Lathe?

There are several reasons why lathes are a great choice for any workshop. Their versatility and precision are unmatched, especially in the case of CNC lathes. They require few operators, and can be quite fast, thus increasing production.

Lathes can be used for processing electrical components. They can be used for facing, the machining operation that produces a flat surface at the end of a workpiece, or turning, which is the removal of excess material from the surface of a workpiece to produce a desired shape and size.

Additionally, boring (removing material from a hole of the workpiece), drilling (the process of making holes by use of drills), knurling (to make an indentation on the border of a workpiece), and chamfering (the process of beveling the end of a workpiece) are other tasks you can perform on engine lathes.

Tips on Buying an Engine Lathe and Accessories

When buying an engine lathe, it’s always best to use a trusted source. Once you’ve determined the type of lathe you or your business needs, finding one on Surplus Record is easy! With our newly redesigned website, searching is easier than ever. You can use the search bar in the header of our website to perform a basic search. Simply type in “engine lathe” or narrow it down by either manual or CNC.

Manufacturers include LeBlond, Clausing, Monarch, Poreba, and more.

We also work with a variety of dealers who specialize in mechanical and CNC lathes. You can also find dealers in your area or by name who specialize in a variety of lath types.

Features that make Engine lathes Great

- Overall value – The overall value of an engine lathe is unmatched when you consider just how much they can do, the variety of materials they can work on, and the general versatility they offer.

- Rigidity – A strong and rigid foundation is key to the efficiency and longevity of an engine lathe. Engine lathes are made with sturdy bases and components that help them stand the test of time and withstand heavy usage.

- Power – One of the reasons why engine lathes are great is the immense power they supply. This is what makes them capable of shaping even the toughest metals without so much as a hiccup.

- Variable RPM controls – The RPM (revolutions per minute) is another great feature of a lathe, allowing you to really dial in on the efficiency and speed needed.

- Locking mechanisms – The locking mechanism allow the engine lathe to keep objects steady while they are being worked on. This allows for greater precision and consistency.