Band saws are power saws used primarily in woodworking, metalworking, and lumbering. Band saws are comprised of a long, thin blade with a band of toothed metal stretched between two or more wheels to cut a variety of materials, including plastic, wood or metal. In this guide, we’ll discuss the basics of how the band saw works, some tips and tricks to keep in mind, and what to look for when searching for the best band saws to buy.

Most Popular Types of Band Saws

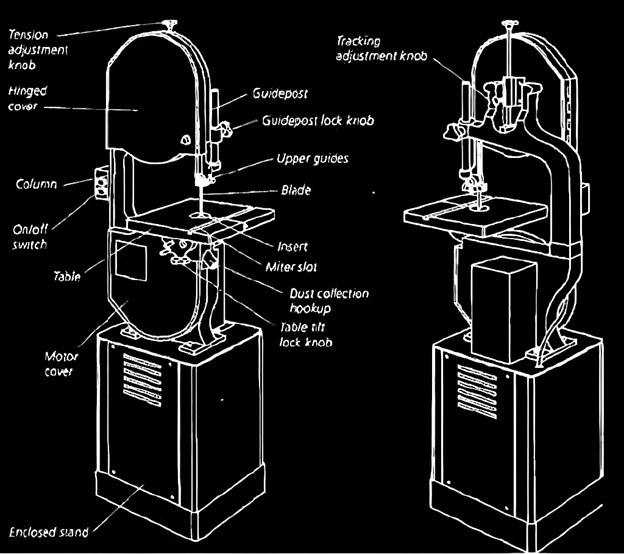

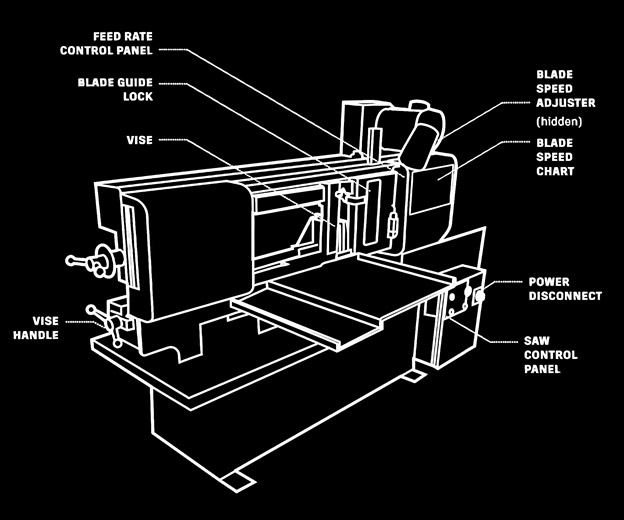

The two most popular and common types of band saws are the Vertical Band Saw (1) and the Horizontal Band Saw (2) which are pictured below.

The Vertical and Horizontal Band Saw are both highly efficient tools but each has a different purpose and function. Understanding which band saw is better for what use, will in turn help you to decide which are the best band saws to buy.

Vertical Band Saws

The biggest advantage of vertical band saws is that they are excellent for small detail cutting, especially with wood-based materials. The operator will “push” their workpiece into the band saw’s stationary blade and can easily cut out a variety of shapes or even curvatures. Vertical band saws are a popular machine found in small/home workshops and are more commonly associated with woodworking, however they are also practical for some metalworking projects (although it is limited by how thick a metal section it can cut). A minor downside to vertical band saws is operational safety, as direct human intervention and control of the workpiece is required, thus increasing the risk of injury. However, with proper training and care the vertical band saw is a machine that is very safe to use. Have a look through our available used vertical band saws for sale here.

Horizontal Band Saws

Alternatively, the horizontal band saw is a very safe machine as the workpiece is held by clamps when cutting, although when discussing cutting capabilities, the horizontal band saw is not as flexible as the vertical when it comes to precision or odd shapes. It does more than make up for this with its productivity. Horizontal band saws are machines designed for making repetitive, accurate cuts and with the help of built-in backstop systems, repetitive cutting is not only fairly accurate but very quick. Accuracy of a band saw more so depends on the operators set up of the machine and their knowledge of its characteristics. Horizontal band saws are commonly used for both metal, wood and plastic with material thickness and hardness generally not being an issue when cutting (depending on the machine’s size and quality of blade). You can view our range of available used horizontal band saws for sale here.

Uses and Applications

Engineers and inventors struggled with the early prototypes of the band saw. First patented by Englishman William Newberry in 1809, efficient operation proved difficult due to the flexibility of early blades and true band saw functionality was not achieved until Frenchman A. Perin invented a flexible blade in the 1860s. Since then, the band saw has flourished in its production and has progressed greatly, through much trial and error, to become one of the most utilized and useful cutting tools available today. Band saws are most commonly utilized in the metalworking and woodworking industries for a variety of cutting purposes.

In a metalworking workshop, one would always expect to see a large to medium sized horizontal band saw used for cutting of lengths of steel down to the required sizes of a welder, fabricator, fitter or machinist. Welders will often cut at specific angles to create accurate and easy to work upon weld joints. In a metal workshop it would not be so common to see lighter material cut on a band saw or with a vertical band saw as angle grinders are highly utilized and more practical.

In the woodworking world, the vertical band saw dominates, with the horizontal more regularly used for cutting large timber. Vertical band saws are used by woodworkers to cut medium to small material down to size and into specific shapes for furniture making, joinery work and more. The horizontal is great for processing large sections of timber down to more manageable pieces, which could later be processed further and more accurately by a vertical band saw.

What to Look for When Buying a Band Saw

The blade configuration is determined by tooth pitches (teeth per inch, or TPI), which is a crucial factor depending on the application. Another key factor when selecting a bandsaw is its motor. The horsepower required will depend completely upon what you wish to cut and how thick or hard the material is. We recommend you thoroughly understand the job you need to accomplish with your band saw, and then consider the following:

Motor

When selecting a band saw it is important to take note of the capabilities and power of its motor. The horsepower that you require will depend completely upon what you wish to cut and how thick or hard the material is. For lighter work a 1-1 ½ horsepower motor is generally efficient with a 2-3 horsepower being better for heavier work.

Characteristics of the Machine

Understanding what will best suit your work will help with identify machinery characteristics better. For example, a large, heavy-duty band saw could prove impractical when one only wishes to cut 1 mm steel. Start by taking into account the size of different components of the band saw such as the table width, clamp size, base girth and the material the saw is made from and identify whether these match what you wish to use the band saw for. Ability to change blade size is also something to consider if you plan to cut different materials often.

Cutting Capabilities

Vertical and Horizontal band saw are both accurate; however, if you require odd cuts with angles, curves or other patterns, then buying a vertical band saw will be best. If you need to repeatedly cut accurate lengths of different sized material then the horizontal band saw would be more what you are looking for.

Materials to be Cut

As previously stated, a vertical band saw is impractical for cutting thick steel and more specific types such as hardened products, while the horizontal band saw will prove itself more compatible. When woodworking on furniture or precision projects, the vertical band saw is much more effective. It’s important to understand the materials you plan to work with before purchasing a saw.

Accessories

More modern saws have unique accessories available to purchase and depending on one’s requirements, these could prove very practical and helpful. They can often save hours of time and labor! Below we will list some of these accessories and provide a brief description on their practicality to help you with your search for the best band saws:

- Adjustable Lamps or LED Light: Often largely overlooked is the viewability of one’s workspace. By adding an additional lamp/light setup to illuminate your band saw you will not only improve on your accuracy of cutting but save strain on your eyes too.

- Work Clamps: For workpieces of odd shapes, utilizing specialized clamps to hold down your workpiece when cutting will improve accuracy and safety.

- Mobile base: These can be installed or built into the band saws body. They are highly practical for when you need to move the saw often, band saws are HEAVY!

- Jigs and Backstops: Fastenable Jigs and Backstops can make repetitive or specialized cutting work very straightforward by taking away the necessity of re-measuring or following a marked outline repeatedly.

Tips for Finding and Buying Band Saws

When searching for used band saws for sale on our platform, we have attached some of our best tips and tricks to make finding the best band saw to buy a little bit easier.

- Make use of our Location Settings: At the top of the page when on the list for either Vertical or Horizontal Band Saws, enter your desired location and you’ll be taken directly to what we have available in your area.

- Looking for a Band Saw at Auction? On the listing page, select the blue checkbox on your right which says “Auction” to be taken to our available band saws for sale on auction. (Note: auction button only appears if there are band saws currently being auctioned)

- On a Budget? Select the toggle “Sort by Relevance” and then click “Price low to high” to view our cheapest to most expensive used horizontal and vertical band saws for sale.

- Don’t forget the Search Bar: Already know what you are looking for? Utilize our search tab at the top of your page to find specific listings out of our hundreds available.

Quick Access: Band Saw Dealers

- Sterling Machinery Exchange | South El Monte, CA

- C.W. Wood Machinery Inc. | Cincinnati, OH

- Vander Ziel Machinery Sales | Alto, MI

- Yoder Machinery Sales | Holland, OH

At Surplus Record, we understand that the process of searching for the best used band saw can be quite daunting. Our advice is to take your time, do the research, use this band saw buying guide and the process of finding the best band saw will prove quite straightforward, almost easy!

Top manufactures available on Surplus Record for Horizontal Band Saws include: Doall, Hem, Hyd-Mech, Wellsaw, and Amada.

Additionally, top Vertical Band Saw manufacturers include: Marvel, Doall, Tannewitz, Hem, Grob, and more. Surplus Record also provides a variety of other manufacturers for your convenience.