Navigating the landscape of machining equipment can often feel like charting through a complex maze, especially when deciding between milling machines, drill presses, and lathes. Each tool boasts distinct features and specializes in different aspects of the machining process, catering to specific tasks, from shaping and cutting to drilling and finishing. Understanding the nuances, capabilities, and applications of these machines is crucial for anyone looking to make informed decisions in the fabrication, metalworking, or woodworking fields.

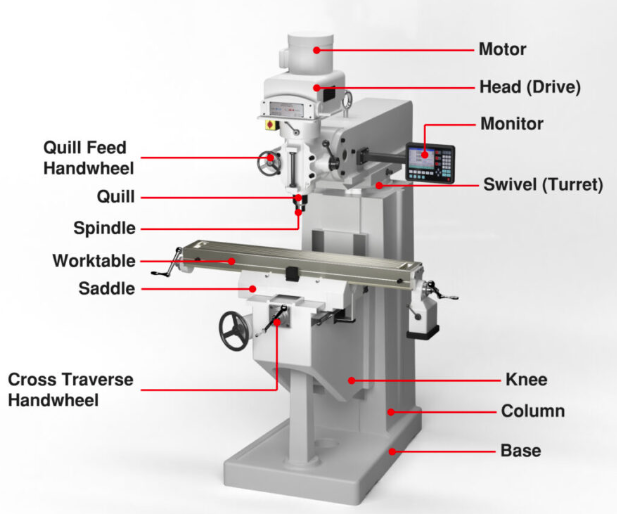

Milling Machines

Milling machines stand out in the machining world for their ability to shape and cut materials with precision and versatility. These powerful tools utilize rotary cutting tools to remove material from a workpiece, enabling them to perform a wide range of operations such as slotting, cutting, drilling, and threading. Unlike other machining tools that move the workpiece while the cutting tool remains stationary, milling machines typically move the workpiece against the rotary cutting tool, allowing for more complex shapes and designs.

What sets milling machines apart is their ability to work on a variety of materials, including metals, plastics, and woods, making them indispensable in many manufacturing and engineering environments. They come in several forms, including vertical and horizontal configurations, each offering unique advantages. Vertical milling machines, for example, are ideal for precision work on smaller pieces, while horizontal milling machines are better suited for heavier and larger projects.

Common uses for milling machines span across industries, from automotive and aerospace manufacturing, where they are used to create components with intricate designs, to electronics and construction. They are also vital in the production of tools, dies, and molds, proving their worth in both prototyping and full-scale production environments. The versatility and precision of milling machines make them a cornerstone of modern manufacturing and metalworking, enabling the creation of parts and products with high accuracy and complex geometries.

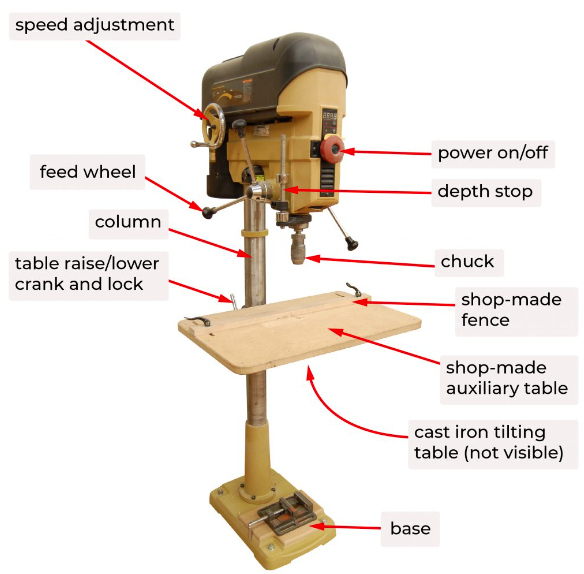

Drill Presses

Drill presses are specialized tools designed for making precise holes in a variety of materials, including metal, wood, and plastic. Central to their design is a powerful motor that drives a drill bit vertically into the workpiece, offering a level of accuracy and consistency that handheld drills struggle to match. The key feature of a drill press is its ability to adjust speed and depth, allowing users to customize the drilling process according to the material’s hardness and the size of the hole needed.

One of the drill press’s strengths lies in its versatility. With the ability to accommodate a wide range of drill bit sizes and types, it can perform operations ranging from simple, straight drilling to reaming, countersinking, and counterboring. This adaptability makes it an essential tool in workshops and manufacturing settings where precision and repeatability are paramount.

Common uses of drill presses are found in both the manufacturing and woodworking industries, where they are utilized for creating clean, precise holes for fasteners, assembly, and joinery. In metalworking, drill presses are indispensable for fabricating metal parts that require exact hole specifications, while in woodworking, they ensure the structural integrity of joints by creating perfectly aligned dowel holes. Beyond these applications, drill presses also find use in DIY projects and crafts, proving their utility across a broad spectrum of activities that require drilling operations.

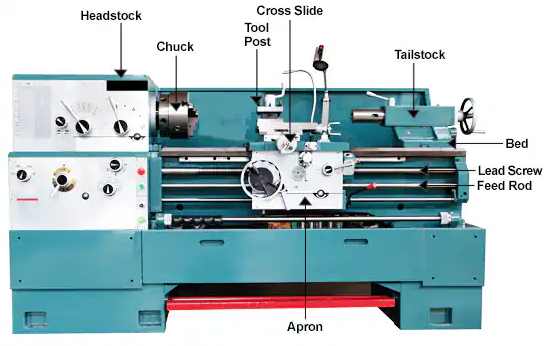

Lathes

Lathes are fundamental machining tools known for their ability to shape materials by rotating the workpiece against a fixed cutting tool. This process, known as turning, allows for the precise machining of cylindrical parts, producing components with smooth surfaces and intricate details. Lathes can work with a variety of materials, including metals, plastics, and wood, making them versatile tools in both industrial and craft settings.

The capabilities of lathes extend beyond simple turning; they are also used for drilling, threading, and cutting tapers, among other operations. By adjusting the cutting tool’s position and the workpiece’s rotation speed, lathes can create parts with precise dimensions and tolerances. Some advanced lathe models even offer features like CNC (Computer Numerical Control) technology, enabling highly accurate and repeatable operations ideal for complex designs and large production runs.

Common uses for lathes are seen across various industries. In manufacturing, they are indispensable for producing components such as shafts, bushings, and screws. The automotive and aerospace sectors rely on lathes for parts that require high precision, such as engine components and landing gear. In the realm of woodworking, lathes are used to create beautifully turned bowls, vases, and furniture legs, showcasing their versatility in both functional manufacturing and artistic creation. Whether for industrial fabrication or crafting intricate pieces, lathes are key tools that have shaped the way materials are worked into finished products.

Milling Machines vs Drill Presses

Milling machines and drill presses serve distinct roles in machining, each optimized for specific tasks. Milling machines are the multitaskers of the machining world, capable of cutting, shaping, and finishing materials into complex geometries. They work by moving a workpiece against a rotating cutting tool, allowing for operations across multiple axes to craft detailed three-dimensional shapes. Their versatility makes them suitable for intricate projects where precision and variety in shaping are required.

Drill presses, in contrast, are specialists in drilling precise holes. They maintain accuracy by securing the workpiece and moving the drill bit vertically with adjustable speeds and depths. Though primarily focused on drilling, they can also handle reaming, countersinking, and tapping. However, their capabilities are limited compared to the broad range of operations a milling machine can perform.

The main difference lies in their applications: milling machines are chosen for complex shaping and detailed work on various materials, while drill presses are preferred for projects demanding high precision in drilling.

Drill Presses vs Lathes

Drill presses and lathes, while both essential in the machining field, are designed for fundamentally different operations. Drill presses excel in creating precise, vertical holes in a workpiece. They are highly accurate for drilling tasks, offering control over depth and speed to ensure consistency across multiple holes. This specialization makes drill presses ideal for projects requiring meticulous drilling operations, such as creating bolt holes or preparing sites for dowels in joinery.

Lathes, on the other hand, are primarily focused on turning operations. They rotate the workpiece against a stationary cutting tool to shape, cut, and finish cylindrical parts. Lathes can perform a variety of tasks beyond turning, including drilling and threading, but their main strength lies in their ability to create symmetrical objects with smooth finishes.

The choice between a drill press and a lathe depends on the nature of the work. Drill presses are the go-to for precision drilling needs, while lathes are unmatched in their capacity to shape and finish rotational parts.

Lathes vs Milling Machines

Lathes and milling machines, though both key players in the machining arena, cater to distinct aspects of the manufacturing process. Lathes are the masters of turning operations, specializing in cutting, sanding, drilling, and deformation of workpieces to create symmetrical parts around an axis. Their primary function revolves around shaping materials by rotating them against a fixed cutting tool, ideal for producing cylindrical shapes like shafts, knobs, and bushings with high precision.

Milling machines, in contrast, boast versatility in cutting and shaping operations across multiple axes. Unlike lathes, which achieve precision through rotation of the workpiece, milling machines use a rotating cutting tool to remove material from a stationary workpiece. This allows them to execute a wide range of tasks such as cutting, drilling, and slotting, making them indispensable for creating complex geometries and parts with intricate details.

The decision between a lathe and a milling machine ultimately hinges on the specific manufacturing needs. Lathes excel in producing round, symmetrical objects, while milling machines are preferred for detailed, multi-dimensional shapes.

Exploring the distinct capabilities of milling machines, drill presses, and lathes reveals the diverse landscape of machining tools, each suited to specific tasks and projects. Whether you’re shaping, drilling, or turning, the key is to choose the tool that aligns with your project’s needs. If you’re looking to expand your workshop or replace existing machinery, Surplus Record offers a comprehensive inventory of used and surplus machinery, including high-quality milling machines, drill presses, and lathes. Explore our selection today and find the perfect tool to elevate your manufacturing capabilities.