Specialized welding equipment has existed nearly as long as the process of welding itself. Tooling such as turning rolls, welding positioners and welding manipulators were designed to improve the overall welding process for the operator; they have remained a staple piece of equipment throughout welding history.

For those who are interested in new welding equipment, used welding equipment for sale and where to buy welding equipment, we will do our best to help guide you through this process via this buyers guide. In this guide, we’ll cover how welding equipment functions, tips and tricks to keep in mind, and what to be aware of before you buy welding equipment.

Most Popular Types of Welding Equipment

Through our experience at Surplus Record, we believe some of the most popular and practical pieces of welding equipment include turning rolls, welding positioners and welding manipulators.

These 3 pieces of welding equipment are regularly used throughout the networking and fabrication industry for their usefulness in increasing production speeds via the easier application of welds. Each piece of equipment has a different purpose, which we shall discuss below, and if you are wondering where to buy welding equipment, such as the manipulator, rolls or positioner, you can find a huge variety of these pieces of used welding equipment for sale right here on surplusrecord.com.

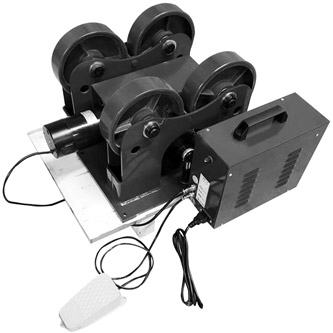

Power Tank Turning Rolls

Power tank turning rolls are excellent tools used for rotating round weld joints such as stainless-steel silos to pipework. The subjective weld job is placed on top of the circular rollers and then rotated either manually or electrically; this allows for clean and consistently placed welds and also saves a lot of time by eliminating the need for the weld operator to pause and reposition.

Power tank rollers are considered a must-have tool for important welding jobs where eliminating mistakes and improving productivity is crucial. Have a look through our available range of used power tank turning rolls for sale.

Welding Positioners

Consider the Welding Positioner as a more advanced version of the Power tank turning rolls. The subjective metal workpiece can be securely fastened into the welding positioner, then it is electrically rotated at an angle to suit your necessities; this allows for a welder/operator to lay consistent welds at all possible angles.

The biggest advantage of welding positioners is productivity, as the likelihood of creating inconsistent and defective welds is reduced while the speed of the welding work is increased. Welding positioners are utilized for tank work, pipework, flange ends, food grade hoppers and many more situations. Check out our available range of used Welding Positioners for sale.

Welding Manipulators

Welding manipulators are generally used alongside a welding positioner to hold the welding torch at different heights, angles, and locations. This relieves the weld operator of the need to weld in uncomfortable locations and also produces high quality welds. The manipulator is set to the correct welding angle and is laid consistently via the assistance of a consistently rotating positioner.

Manipulators are great to use for tank work and pipe welding or basically any metal joint with a curved edge. Weld Manipulators improve the overall safety of welding work as they eliminate the necessity of the weld operator to work at height, the manipulator does this for you. View our available range of used welding manipulators for sale.

Uses and Applications

Welding equipment is designed to improve welding productivity, quality assurance and safety. Within the aeronautical, food-grade, medical, military, nuclear and oil industries, amongst others, welding equipment such as the positioner, manipulator and turning roll are considered vital tools in a means of meeting industrial standards. These tools are used for metal working jobs with circular circumference where a weld is needed to be laid, however the positioner and turning roll can also be used to assist a metalworker with grinding, polishing and other metalwork where accuracy or productivity could be a requirement. Safety is a major factor that many companies take into consideration as the mindset of the metal industry grows and changes; specialized welding equipment increases welding safety drastically by eliminating work hazards such as working at height and in dangerous positions, inhaling gases and with the rotation of workpieces.

It is important to mention that welding equipment is specialized and each differs in its practical application and usefulness. This should be taken into consideration when searching for equipment.

What to Look for When Buying Welding Equipment?

When looking to buy welding equipment for your workshop or project, consider the following to help reduce misunderstanding, disappointment, or objection:

Damage

When you find a piece of industrial welding equipment for sale that suits your specifications, the first thing to consider is internal and external damage. Used welding equipment that is for sale generally has had a hard life, but this isn’t a bad thing. They are designed for heavy use after all, but to avoid making a disappointing purchase you should thoroughly inspect and test the machine for heavy damage, operational faults, and signs of regular maintenance of components. If the previous owner of a machine seems to have dropped it off a crane, this could be less serious than you think. At Surplus Record, we would deem that a well-maintained machine is a better purchase than a pretty one without signs of maintenance.

Size of Your Projects

Welding positioners, manipulators and rolls are available in a variety of sizes ranging from smaller to larger machines. On the smaller end of the scale, machines are more practical for pipework, gas tank welding and tubing. Medium sized machines are fairly flexible with their capabilities and for large machines, they are designed to manage the labor of working with projects in heavy fabrication. Depending on the specific piece of machinery you need, make sure that you understand which piece suits your work intentions and stick with it.

Settings

For example, most welding positioners available will have speed settings and angle settings that will vary. We recommend posing the question to yourself and your company again: What am I going to buy this machinery for? Do I need extremely slow rotational speeds? Or in the case of considering purchasing a welding manipulator, ask yourself: What height will I be needing to weld at on a regular basis? These questions may seem fairly obvious, but it is common for people to believe that one machine can do everything whilst this is not always the case.

Useful Accessories

Let’s cover some practical and productive accessories that you may want to invest in to improve the performance of your piece of welding equipment.

- Torch clamp mount: This could be used on any of the 3 previously mentioned pieces of welding equipment. Having adjustable lighting readily available will not only improve your visibility but your weld quality and productivity.

- Plastic rollers or covering: By having an interchangeable plastic roller set or suitable covers for your turning rolls, you will be less likely to damage or contaminate projects made of stainless steel or aluminum.

- Adjustable roller feet: These are sometimes included in the structure of the machine and sometimes not. If not, attaching adjustable roller feet and legs to your piece of equipment will allow for easier movement around your workspace.

Surplus Record: Tips and Tricks

When questioning where to buy welding machines, Surplus Record is the number one online option available. By searching on our platform you will find a massive variety of welding equipment available. Below we have attached some of our best tips and tricks to make the search to buy a welder a little bit easier.

- Make use of our Location Settings: At the top of the page when on the list for welding equipment, enter your desired location and you’ll be taken directly to what we have available in your area.

- Looking for an Auction: On the listing page, select the blue checkbox on your right which says “Auction” to be taken to our available welding equipment being auctioned off.

- On a Budget: Select the toggle “Sort by Relevance” and then click “Price low to high” to view our cheapest to most expensive welding positioners or manipulators for sale.

- Don’t forget the Search Bar: Already know what you’re looking for? Utilize our search tab at the top of your page to find specific listings out of our hundreds available.

Quick Access: Welding Equipment Dealers

- Kevins Equipment Co | Texas

- Joe Fuller LLC | Texas

- All-Fab Corp | Michigan

At Surplus Record, we understand that the process of searching for new and used welding equipment can be quite daunting. Our advice is to take your time, do the research and use our specialized welding equipment buying guide; the process of finding the best industrial welding equipment for sale will be straightforward. Almost easy!

Our top manufactures available on Surplus Record for:

Turning Rolls

Welding Manipulators:

Welding Positioners

Need More Help or Information on Welding Equipment?

Still can’t find what you’re looking for or need more advice from a welding professional dealer? Head on over to the “Wanteds” section of our website and select “Buy” at the top and “General Equipment & Machine Tools” for the industry. Fill out the form and a dealer that specializes in welding machinery will get back to you asap. It’s free to do, and dealers are happy to help out!