Refrigeration compressors are the beating hearts of cooling systems, driving the circulation of refrigerant and enabling the efficient transfer of heat. These powerful devices play a crucial role in refrigeration and air conditioning applications, keeping our food fresh, our spaces cool, and our comfort levels optimal. In this buying guide, we’ll delve into the world of refrigeration compressors, exploring their function, types, and importance in various industries. Join us as we uncover the inner workings and undeniable significance of refrigeration compressors in the realm of cooling technology.

Popular Types of Refrigeration Compressors

Refrigeration compressors come in various types, each with its own unique design and operating principles. These compressors are key components in refrigeration and air conditioning systems, responsible for circulating refrigerant and maintaining the desired temperature. Here are some popular types of refrigeration compressors:

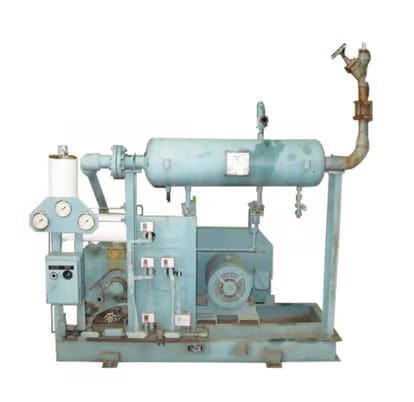

- Piston (Reciprocating) Compressors: Piston compressors, also known as reciprocating compressors, use a piston and cylinder arrangement to compress the refrigerant. The piston moves back and forth, drawing in the refrigerant during the suction stroke and compressing it during the compression stroke. These compressors are known for their durability, efficiency, and wide range of capacity options. They are commonly used in both small-scale and large-scale refrigeration applications, such as household refrigerators, commercial coolers, and industrial refrigeration systems.

- Rotary (Screw/Scroll/Vane) Compressors: Rotary compressors encompass several subtypes, including screw, scroll, and vane compressors.

- Screw Compressors: Screw compressors feature two interlocking rotors that compress the refrigerant. As the rotors rotate, the refrigerant is trapped and compressed in the helical grooves. These compressors are known for their high efficiency, low noise levels, and continuous operation. Screw compressors are widely used in commercial refrigeration, air conditioning, and industrial cooling applications. Within this field of screw compressors are also Bare Screw Compressors which is sold without any of the other features like the cooling system or enclosure or control system.

- Scroll Compressors: Scroll compressors utilize two spiral-shaped scrolls, one that’s fixed and one orbiting, to compress the refrigerant. The motion of the orbiting scroll creates increasingly smaller pockets, trapping and compressing the refrigerant. Scroll compressors are appreciated for their reliability, quiet operation, and compact design. They are commonly found in residential and light commercial air conditioning systems.

- Vane Compressors: Vane compressors employ a rotor with sliding vanes that move in and out of the rotor slots, compressing the refrigerant. These compressors are known for their simplicity, compactness, and smooth operation. Vane compressors are often used in smaller refrigeration systems, refrigerated transportation, and automotive air conditioning applications.

- Centrifugal Compressors: Centrifugal compressors use high-speed rotating impellers to accelerate the refrigerant. The refrigerant is then directed to diffuser blades, where it is slowed down and converted into pressure. Centrifugal compressors are recognized for their high capacity, large flow rates, and excellent energy efficiency. They are commonly used in large-scale industrial refrigeration systems, air conditioning for commercial buildings, and process cooling in industries such as petrochemical and manufacturing.

Piston vs Rotary vs Centrifugal Refrigeration Compressors

Piston, rotary, and centrifugal compressors are popular types of refrigeration compressors, each with distinct characteristics. Here’s a brief comparison:

- Piston Compressors:

- Design: Simple design with fewer moving parts.

- Capacity Range: Wide range, suitable for small to large applications.

- Efficiency: High efficiency at full load, may decrease at partial load.

- Noise Level: Tends to produce more noise.

- Rotary Compressors:

- Design: Compact and space-saving.

- Efficiency: High energy efficiency, stable performance across a range of conditions.

- Noise Level: Lower noise levels compared to piston compressors.

- Applications: Used in residential, commercial, and industrial systems.

- Centrifugal Compressors:

- Design: Complex design with multiple stages.

- Capacity Range: High capacity and large flow rates.

- Efficiency: Excellent energy efficiency, especially in high cooling loads.

- Noise Level: Lower noise levels compared to piston compressors.

- Applications: Used in large-scale refrigeration, air conditioning, and industrial processes.

Each type of refrigeration compressor offers specific advantages in terms of capacity, efficiency, noise levels, and application suitability. The selection of the compressor type depends on factors such as cooling requirements, space constraints, energy efficiency goals, and budget considerations.

What to look for when buying Refrigeration Compressors

When purchasing refrigeration compressors, several factors should be considered to ensure the selection of the most suitable unit for your specific needs. Here are key aspects to look for when buying refrigeration compressors:

- Cooling Capacity: Consider the cooling capacity of the compressor, which is typically measured in BTUs (British Thermal Units) or tons. Assess your cooling requirements to determine the appropriate capacity for your application. Factors such as the size of the space, cooling load, and temperature requirements will influence the required cooling capacity.

- Required Space: Evaluate the available space for installing the refrigeration compressor. Consider the dimensions, weight, and installation requirements of the compressor to ensure it can be accommodated in your desired location. Check clearance requirements for proper ventilation and access for maintenance.

- Energy Usage: Energy efficiency is a vital consideration to reduce operational costs and environmental impact. Look for compressors with high energy efficiency ratings, such as those certified by ENERGY STAR or other efficiency standards. Energy-efficient compressors can help reduce electricity consumption and save on long-term operating expenses.

- Noise: Take into account the noise level generated by the compressor. Consider the environment in which it will be operating, such as residential, commercial, or industrial settings. Look for compressors with noise-reduction features or low decibel ratings to ensure a quieter operation, especially in noise-sensitive areas.

Additionally, consider other factors such as reliability, durability, maintenance requirements, and compatibility with the refrigerant and system components used in your application. Consulting with a reputable supplier or HVAC professional can provide valuable guidance in selecting the right refrigeration compressor based on your specific requirements.

By carefully evaluating these factors, you can choose a refrigeration compressor that provides the necessary cooling capacity, fits within the available space, operates efficiently, and meets your noise level preferences.

Applications for Refrigeration Compressors

Refrigeration compressors find widespread use in various industries and applications, playing a critical role in cooling, preserving, and maintaining desired temperatures. Here are some key applications where refrigeration compressors are commonly employed:

- Commercial and Industrial Refrigeration: Refrigeration compressors are the backbone of commercial and industrial refrigeration systems. They are used in supermarkets, grocery stores, restaurants, and warehouses to keep perishable goods, such as food and beverages, fresh and safe for consumption. Industrial refrigeration systems are also essential for storing and preserving large quantities of goods in cold storage facilities, distribution centers, and food processing plants.

- HVAC and Cooling Systems: Refrigeration compressors are integral components of HVAC (Heating, Ventilation, and Air Conditioning) systems. They provide cooling for residential, commercial, and institutional buildings, ensuring comfortable indoor temperatures and maintaining air quality. HVAC systems with refrigeration compressors are commonly used in offices, schools, hospitals, shopping malls, and other public spaces.

- Ice-making: Refrigeration compressors are essential for ice-making applications, including ice production for commercial purposes, such as restaurants, bars, and hotels. Ice-making machines utilize refrigeration compressors to cool and freeze water, producing ice cubes or other forms of ice for various uses, including beverage cooling, food preservation, and medical applications.

- Medical and Laboratory Environments: Refrigeration compressors play a vital role in medical and laboratory settings where precise temperature control is crucial. They are used in medical refrigerators and freezers to store vaccines, medications, blood products, and other sensitive biological materials. In laboratories, refrigeration compressors are utilized in equipment like ultra-low temperature freezers, incubators, and climate-controlled chambers for research and sample preservation.

- Material Transport: Refrigeration compressors are employed in transportation vehicles, such as refrigerated trucks, vans, and containers, to maintain controlled temperatures during the transport of perishable goods. This ensures that goods like fresh produce, frozen food, pharmaceuticals, and chemicals are delivered in optimal condition, preserving their quality and integrity.

- Manufacturing and Processing: Refrigeration compressors are extensively used in manufacturing and processing industries. They are vital for temperature control in various processes, such as food and beverage production, chemical manufacturing, pharmaceutical manufacturing, and metalworking. Refrigeration compressors enable precise cooling and preservation of raw materials, intermediate products, and final goods during manufacturing and processing operations.

These applications highlight the versatility and importance of refrigeration compressors in maintaining optimal temperatures, preserving goods, and supporting essential processes across a wide range of industries.

Accessories for Refrigeration Compressors

To enhance the performance, safety, and efficiency of refrigeration systems, various accessories are available for use with refrigeration compressors. These accessories help optimize operation and protect the components of the system. Here are some important accessories commonly used with refrigeration compressors:

- Filters and Isolators: Filters and isolators are employed to ensure the cleanliness and reliability of the refrigerant circulating within the system. Filters remove contaminants, such as dirt, debris, and moisture, from the refrigerant, preventing potential damage to the compressor and other system components. Isolators help minimize vibrations and noise, isolating the compressor from the rest of the system.

- Accumulators: Accumulators are essential accessories in refrigeration systems, particularly those with varying load demands or operating conditions. They act as temporary storage tanks for refrigerant, ensuring a consistent supply to the compressor. Accumulators also assist in the separation of liquid and vapor refrigerant, improving the efficiency and performance of the system.

- Mufflers: Mufflers, also known as silencers, are used to reduce noise generated by the operation of the refrigeration compressor. They are installed in the discharge or suction lines of the compressor to attenuate noise levels, creating a quieter working environment. Mufflers help to minimize noise pollution and promote a more comfortable atmosphere in commercial and industrial settings.

- Pressure Relief Valves: Pressure relief valves are crucial safety accessories in refrigeration systems. They are designed to protect the compressor and other system components from excessive pressure build-up. In the event of overpressure, the relief valve opens, allowing refrigerant to escape and prevent potential damage. Pressure relief valves help maintain the integrity and safety of the system, safeguarding against catastrophic failures.

These accessories work in conjunction with refrigeration compressors to improve system performance, reliability, and safety. By utilizing filters and isolators, accumulators, mufflers, and pressure relief valves, operators can enhance the efficiency of the refrigeration system, protect components from damage, reduce noise levels, and maintain system integrity. It is important to consult with manufacturers or HVAC professionals to select the appropriate accessories based on the specific requirements and configuration of the refrigeration system.

Tips & Tricks

You won’t have much trouble finding a specific type of refrigeration compressor on Surplus Record. At the top of all the pages on our website, you’ll see a search bar. Type the phrase “Refrigeration Compressor” into it, click on the category that drops down, and examine the options we have available.

We also work with a variety of dealers who specialize in refrigeration compressors. You can also find dealers in your area or by name who specialize in refrigeration compressors.