The advent of contemporary processing systems is rooted in the monumental transformations of the Industrial Revolution. This critical period was characterized by a significant transformation in manufacturing and processing methods, driven by innovative breakthroughs in engineering and science. The revolution spurred the creation of new, durable products tailored to meet the increasing demands for durability and practicality, leading to the emergence of essential industrial equipment like processing vessels and kettles.

These elements have become integral in a wide range of industries, celebrated for their efficiency and adaptability in managing intricate industrial processes. This guide explains the core principles behind the functionality and importance of processing vessels and kettles, providing you with a comprehensive understanding of their applications and valuable guidance for the procurement process. Learn the intricacies of choosing second-hand industrial equipment so you can make a well-informed decision when searching for high-quality vessels and kettles.

What are Processing Vessels & Kettles?

Within the realm of manufacturing, processing, and production-oriented industries, Processing Vessels and Kettles stand as fundamental components, each serving distinct yet pivotal roles. This exploration delves into the nuances of these apparatuses and their respective functionalities.

The Processing Vessel: A Multifaceted Container

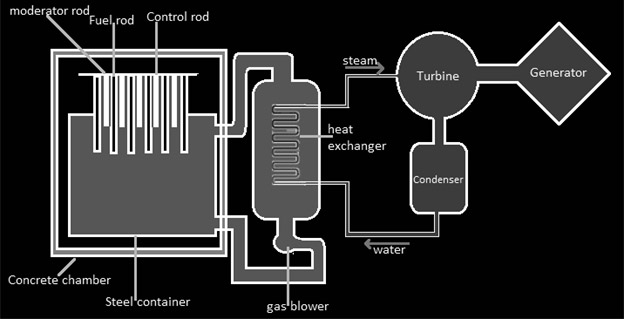

At its core, a Processing Vessel is a robust steel tank meticulously designed and outfitted with essential components and controls to facilitate a specific sub-process within a larger operational framework. It excels in various tasks such as storage, blending, cooling, separation, purification, and altering the physical state of materials. Processing Vessels are versatile, capable of being integrated at any juncture within a production line, whether at the outset, midpoint, or culmination of the process. They can accommodate a wide spectrum of materials—from simple water to complex nuclear chemicals—and are lauded for their adaptability.

Manufactured from a variety of materials including stainless steel, titanium, mild steel, and even plastics, these vessels are customizable in terms of size, thickness, capacity, and volume to meet specific requirements. Furthermore, they are engineered to withstand significant pressures and loads, showcasing their reliability in diverse applications.

The Processing Kettle: An Industrial Culinary Marvel

Echoing the simplicity of a domestic kettle, the Processing Kettle operates on a grander scale, designed to heat, cool, mix, and store large volumes of produce akin to a colossal stovetop pot. Primarily found in food processing and industrial kitchen settings, these kettles are engineered for efficiency and versatility.

Variants include steam-jacketed kettles, which utilize dual-wall construction for steam-based heating, electric kettles powered by electricity for heating and mixing, and agitator kettles designed for intensive mixing tasks with various motion options. This makes Processing Kettles indispensable tools in food production, capable of handling complex mixing and cooking tasks with precision and control.

Processing Vessels and Kettles are integral components of the industrial landscape, each tailored to fulfill specific roles in the vast domain of manufacturing and processing. Their design, functionality, and application versatility make them essential for a wide array of industries, ensuring efficiency, safety, and quality in production processes.

Uses and Applications

Processing equipment, specifically vessels and kettles, is fundamental to achieving operational efficiency across a broad range of industries. These tools are crucial in fields as diverse as Food, Agriculture, Hospitality, Chemical, Medical, Paper, Pulp, and Plastic Processing, showcasing their versatility and essential role in various sectors.

In the hospitality industry, for example, processing kettles are indispensable for the large-scale and efficient production of food. Widely used by restaurants, bakeries, and confectioneries, these kettles enhance the mixing of solids and liquids, as well as the cooking and preparation processes. Their capacity to manage substantial volumes of foodstuffs with precision and efficiency is invaluable for entities striving to uphold high standards of productivity and quality.

Furthermore, processing vessels and kettles play pivotal roles in numerous other domains. They are key in the chemical industry for managing reactions under controlled conditions, in the medical and pharmaceutical fields for the creation and preparation of drugs, and in agriculture for processing crops and chemicals. The paper and pulp industry depends on them for material treatment and processing, while the plastic processing sector utilizes them for blending and polymerization reactions.

This extensive utility highlights the vital function of processing equipment in contemporary industry, acting as a pillar of innovation, production, and operational efficiency across multiple fields. Their flexibility and the possibility for customization to meet specific operational needs render them indispensable tools in the pursuit of excellence and high-quality output in production processes.

What to Look for When Buying a Processing Vessel or Kettle?

Embarking on the journey to purchase used processing equipment requires a nuanced understanding of the factors that ensure your investment meets your operational needs effectively. Below are refined pointers to guide you through the decision-making process when selecting a used Processing Vessel or Kettle.

Size and Capacity: Tailoring to Your Needs

The foremost consideration is identifying the size and capacity that align with your operational requirements. The spectrum of processing equipment is vast, ranging from modest 1-gallon units to expansive models exceeding 10,000 gallons. An effective strategy to streamline your search involves specifying the capacity, such as “100 gallon,” to filter through available options and pinpoint the equipment that matches your specifications.

Provenance and Maintenance History: Ensuring Reliability

Delving into the history of the equipment is crucial to ascertain its reliability and maintenance upkeep. Engage with the seller to uncover the frequency of servicing and the measures taken to preserve the equipment’s functional integrity. This proactive inquiry can safeguard against the acquisition of neglected machinery, thus optimizing your investment’s value.

Design Specifications: Compatibility with Your Process

Understanding the intended use and design specifications of the equipment is essential to ensure compatibility with your processing needs. For instance, equipment designed for oil storage may not be suitable for dairy applications. Recognizing the specific design intentions and operational capabilities of the equipment enables a more informed and effective selection process.

Technical Specifications: Precise Requirements

It is imperative to accurately define the technical specifications required for your operations, including square footage, gallon capacity, and PSI ratings. This detailed understanding facilitates the selection of equipment that precisely meets your processing demands.

Useful Accessories and Equipment

Ergonomic Accessibility Solutions

To ensure seamless access and maintenance, incorporating ergonomic solutions like platforms, balustrades, and stairwells around larger processing units is vital. These additions are not only safety measures but also facilitate easy access for routine inspections, maintenance, and operational adjustments, contributing to smoother workflow and reducing downtime.

Specialized Cleaning Systems

Maintaining the cleanliness and hygiene of processing equipment is non-negotiable, especially in industries where purity and sanitation are crucial. Investing in specialized cleaning systems tailored to your specific equipment can prolong its lifespan, maintain efficiency, and ensure compliance with industry standards. Consultation with a specialist to select the most appropriate cleaning method and equipment for your needs is recommended.

Precision Temperature Monitoring

Accurate temperature control is essential in many processing operations to ensure product quality and process reliability. Implementing both integrated and external thermometers allows for continuous monitoring and adjustments as necessary, ensuring that production conditions remain within optimal ranges. This dual approach to temperature monitoring can prevent process deviations and product spoilage.

Advanced Control Panels

Custom-designed control panels offer unparalleled control over processing parameters, including pressure, flow rate, temperature, and more. These sophisticated systems can automate process adjustments in real-time, enhancing efficiency and reducing the need for manual intervention. By integrating these control panels, operators can achieve a higher level of precision and reliability in their processing operations.

Safety Enhancements

Safety accessories, such as pressure relief valves, emergency shut-off systems, and leak detection sensors, are crucial for preventing accidents and ensuring the well-being of the workforce. These systems should be selected based on the specific risks associated with the processing materials and methods employed.

In conclusion, the thoughtful selection and integration of these accessories into your processing equipment setup can lead to significant improvements in efficiency, safety, and product quality. Tailoring these enhancements to the unique requirements of your operations will ensure that your processing equipment operates at its full potential, delivering optimal results consistently.

Tips and Tricks for Buying a Vessel or Kettle

To help you search for used storage and processing containers for sale on our platform, we have attached some of our best tips and tricks to make finding your ideal piece of processing equipment a little bit easier.

- Utilize Geolocation for Precision Searches: Streamline your quest by employing the geolocation feature. Simply input your desired location in the designated field at the top of the equipment listings page. This instantly filters the search results, showcasing only the items available within your specified vicinity, thus making your search more targeted and efficient.

- Discover Auction Deals: For those seeking competitive pricing and unique finds, our auction feature is a treasure trove. Navigate to the listing page and select the “Auction” option. This action will reveal an array of products currently available through auctions, offering you the chance to snag excellent deals on high-quality equipment.

- Shop Within Your Budget: Our platform caters to all budgetary requirements. By adjusting the “Sort by Relevance” feature to “Price low to high,” you can easily access our listings in ascending order of price. This allows you to explore our most affordable options first, ensuring you find equipment that aligns with your financial constraints.

- Advanced Search Functionality: For those with specific requirements, the search bar is your gateway to precision. Located prominently at the top of every page, this feature enables you to conduct searches using keywords, model numbers, or equipment types, filtering through our extensive database to directly find the listings that match your criteria.

- Explore Through Categories: Dive deeper into our inventory by exploring equipment through categorized listings. This method allows you to browse specialized equipment categories, helping you to uncover the exact type of processing vessels and kettles relevant to your needs.

- Direct Communication with Sellers: Once you’ve pinpointed potential equipment, our platform facilitates direct communication with sellers. This feature empowers you to inquire further about the items, negotiate prices, or request additional information, ensuring a transparent and satisfactory purchasing experience.

Processing Vessel & Kettle Dealers

Surplus Record’s network of trusted dealers specializes in providing a wide array of quality used industrial processing equipment, ensuring you have access to expert advice and a diverse selection of machinery to meet all your operational needs.

- Perry Videx | New Jersey

- Frain Industries | Illinois

- Federal Equipment Co. | Ohio

At Surplus Record, we recognize that finding the right used industrial processing kettles and vessels can seem overwhelming. Our suggestion is to approach this task with patience, conduct thorough research, and leverage the insights provided in this buying guide. By doing so, your journey to securing the ideal used processing equipment will become manageable and straightforward.

Processing Vessel and Kettle Manufacturers

Surplus Record proudly features a premier selection of used processing vessels and kettles from industry-leading manufacturers, ensuring high quality and reliability for your industrial needs. Our top manufacturers include:

Seeking further assistance or more detailed information about our selection of Processing Vessels and Kettles? If you’re unable to find exactly what you need or require additional guidance from a seasoned professional, we invite you to visit the “Wanteds” section of our website.

Simply select “Buy” and then choose “Processing Equipment” as your industry category. Complete the form with your query, and a specialized dealer in processing machinery will promptly respond to your request. This service is complimentary, and our knowledgeable dealers are eager to assist you in finding the perfect equipment solution for your operations.