This article will serve as a Jib Cranes Buyers Guide, describing how they work, the most popular types of models, what a buyer should look for when purchasing a jib crane, and the various applications and uses of these sorts of cranes.

Popular Types of Jib Cranes

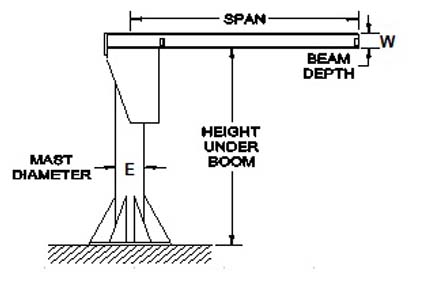

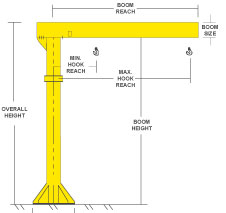

Defined generally, a crane is a piece of heavy machinery used to lift large loads. They employ the principles of several simple machines such as pulleys and levers in order to do so and are comprised of common parts such as a mast (the vertical arm that supports the crane mechanism), a hoist (a cranking mechanism that helps move the load), and the ropes (heavy-duty metal cables that do the actual lifting). Cranes vary widely in physical dimensions, lifting capacity, and end-use applications.

Some cranes have a component called a jib, a horizontal arm that supports the rope and holds the load away from the mast. While certain cranes dub the arm supporting the ropes a “boom”, it gets called a “jib” when it extends horizontally from the mast. (Note that we’re being a bit reductionistic with this definition; sometimes cranes with booms have supporting or extending arms that can maneuver into a roughly horizontal position, and these are also called jibs.)

Jib cranes are generally fixed cranes with the ability to rotate from 180 to 360 degrees and to lift loads ranging from 250 pounds to 15 tons. What they lack in mobility, they more than make up for in lifting strength and relative ease of operation and repair. Jib cranes excel at repetitive lifting tasks, although they face some significant downsides that we will detail in our “Advantages and Disadvantages” section down below.

While jib cranes are somewhat simply designed, consisting of a mast, a jib beam, and a hoist, they come in many different configurations, including the following:

- Freestanding. This most common type of jib crane has earned it popularity due to its configuration flexibility. Freestanding jib cranes can be installed nearly anywhere with a big range of heights, lift capacities, and spans (i.e., jib lengths). They are typically mounted on base plates, a steel plate with a poured concrete foundation, or a steel sleeve anchored to a plate and then reinforced with concrete. This final configuration allows for the relocation of the jib system to a new site.

- Foundationless. Similar to freestanding jibs, these cranes do not actually have foundations and are simply mounted to a concrete slab. They can be easily installed into existing spaces, but they have much lower lifting capacities.

- Articulating. Articulating jib cranes have two arms attached to the mast, which means that this jointed jib has maximum maneuverability. Articulating cranes can reach around corners and under equipment. They usually cannot lift heavier loads.

- Mast Type. These cranes work similarly to foundationless jibs, but they require a supporting overhead beam or some such similar structure for support.

- Wall Mounted. As the name suggests, wall-mounted jib cranes use a wall mount for structural support. They may also require a tie rod to hold the assembly in place. These cranes have restricted rotation, which is typically 180 to 200 degrees.

- Wharf Cranes. These marine cranes require special weatherization to prevent damage from the elements.

Portable vs Semi-Portable vs Mobile Cranes

When describing jib cranes that you can move, you may encounter adjectives such as “portable,” “semi-portable,” and “mobile.” All of these terms simply highlight the fact that a particular crane can be relocated to a new space with a certain amount of effort. For instance, small workshop-type cranes may come on a wheeled tripod, while heavier-duty models feature steel slab supported by extending leveling arms. Some even categorize foundationless jib cranes as portable since they’re easy to install almost anywhere.

What to Look for When Buying Jib Cranes

Every piece of equipment has different considerations that one must remember during the purchasing process, and jib cranes are no different. As you make your selection, keep the following items in mind:

- Know how you’ll get electricity to the jib

- Consider the cost of the concrete foundation

- Be sure to account for hook coverage

- For jibs used outdoors, upgrades (e.g., weatherizing) are a must

- Consider the strength of your building column

- Ensure the crane’s capabilities will work with your end-use application. What material will you need to move? How far will you need to move it? What are its physical characteristics? What will be the path of travel?

Advantages and Disadvantages

Jib cranes enjoy numerous advantages. They’re relatively simple in design, which makes them easy to install, operate, and service. They’re usually smaller than other types of cranes and function well in constrained areas. They can also accommodate a wide array of load sizes and types.

However, jib cranes have notable limitations and weaknesses that mean they aren’t appropriate for every kind of task. Jibs are typically of a fixed length, meaning that you must carefully plan exactly how you’ll use them. (Note that articulating jib cranes have more flexibility than other options.) Permanent jib cranes (e.g., mast type, wall mounted, freestanding) are expensive to install, but choosing a more portable option greatly decreases the load the crane can manage. Finally, jib cranes aren’t intended to work across wide areas. They are smaller in size and function best in confined spaces.

Applications & Uses

Given their various configurations, design benefits, and unique constraints, it makes sense that jib cranes excel at certain tasks, some of which include the following:

- Widely used in workstations, storage areas, industrial yards, and other fixed or localized places

- Excel at material handling over short distances or in places with serried storage

- Can be used in combination with a large overhead crane for material handling

- Can be used for suspension of tools

- Are preferred for economical outdoor applications

- Do not work well in dangerous applications, including flammable, explosive, and corrosive working contexts

Accessories & Components for Jib Cranes

Most jib crane accessories and components fall into the category of spare parts. Some common replacement items are:

- Reach/Boom

- Mast/Pillar

- Movable Hoist

- Trolley

- Rotation Equipment

- Electrification/Pneumatic Equipment

- Controls

- Hook

Tips & Tricks

The most important trick that you can exercise to get the best possible deal on a jib crane is to carefully plan out your use case and match your selection to the application. Purchasing a machine with extra capacity or one that requires expensive installation doesn’t make sense if a lighter-duty piece of equipment would suffice just as well.

Also, don’t feel a need to pay for a new jib crane. You can get exactly the type of machine you need at a much lower price by buying used. Surplus Record offers great deals on quality used equipment each and every day.

Finding Jib Cranes on Surplus Record

It’s easy to find the specific type of jib crane that you want on Surplus Record. Type “jib cranes” into the search bar at the top of any of our pages, hit enter, and peruse the options we have available.

Featured manufacturers include Abell-Howe, Contrx, Gorbel, and Morgan.

We also work with a variety of dealers who specialize in jib cranes. You can also find dealers in your area or by name who specialize in jib cranes.