Boilers have been around for centuries, and with good reason. From rudimentary kettle boilers to modern electric boilers, this guide aims to help you in purchasing a boiler for your business, home, or workshop.

History of the Boiler

Early steam-generating boilers can be dated as far back as the 1700s and 1800s. These were kettle-type boilers which featured a water-filled vessel above a fire source. The heated water/fluid would then vaporize, exiting the boiler for use in heating applications or other processes.

It’s unclear exactly who developed the first steam-generating boilers, but most agree that the Babcock & Wilcox Company in New York City made it a household name. Founders George Babcock and Steven Wilcox were the first to patent their unique boiler design, which utilized tubes inside a firebrick-walled box to generate steam. The brick helped the combustion process by recirculating the heat back into the furnace area.

Around the same time, The Stirling Boiler Company, owned by O.C. Barber designed a boiler called the H-type boiler which was much larger and used three different drums to help circulate the water and steam flow throughout the boiler. In 1907 the two companies merged, renaming their boiler the H-type Sterling which eventually became one of the best-selling boilers of its time due to its ability to produce up to 50,000 pounds of steam per hour.

Other companies later developed the Type E stoker boiler, once which used a traveling grate at the base of the boiler to transport the fuel (lump coal) across the inside of the boiler. As the fuel moved across the inside of the boiler, it was burned, leaving the ash to drop into a hopper. The advent of these boilers made way for utility companies to form across the country to generate and distribute electricity to various industrial and residential markets.

Popular Types of Steam Boilers

There are a number of steam boiler types available, each a bit different and delivering distinct advantages. Some of the more common types are:

Firetube

Firetube boilers are regarded as the best boiler for steam generation, particularly in industrial settings. These are usually manufactured and packaged as a unit, with the only requirement being a connection to fuel and water supplies. They are very reliable in terms of producing large amounts of steam consistently. Firetube boilers consist of steel tubes arranged inside the water tank. The fuel is then passed through the tubes to heat the water and produce steam. These boilers are typically powered by natural gas. You should also expect to get more steam from a boiler with higher horsepower.

Watertube

These are also gaining popularity due to their versatility as a steam generator. For this boiler type, the water remains inside the tube as the heating happens from the outside. Watertube boilers are the preferred boiler type at large facilities that require substantial steam, such as refineries, and pulp and paper manufacturing plants. Watertubes are notable for their ability to keep high pressure up to around 1000 psi, compared to just around 250 psi for firetube boilers. Additionally, it wastes no time between the start of operation and steam production.

Hot Oil

Many industry experts will tell you that hot oil boilers are preferable to steam. Their most notable benefit over steam boilers is that they do not need pressurization, which means less monitoring and a decreased risk of combustion. Hot oil is also a lubricant and can safely run though a thermal heating system without causing corrosion or freezing. Overall, hot oil boilers are safer, more efficient, require less supervision and do not need to be operated by a licensed boiler operator.

Hydronic

Hydronic is a general term that represents heating systems based on water. Hydronics involve heating water for dispersal to parts of a building through pipes. These systems are well-liked for their ability to deliver heat precisely when and where needed. Additionally, they provide safety, efficiency, affordability, and durability.

Electric

These are smaller, safer, more environmentally conscious boilers that operate rather quietly. They do not require natural gas, oil, or any other fossil fuel, therefore there is no chance of explosion or emission of harmful gas. An electric boiler is perfect for locations where there are restrictions on gas emissions. Electric boilers can however be quite expensive and are usually advisable only where the electricity costs are reasonable.

Gas Fire Boilers

Gas fire boilers can be fueled by either natural gas or propane and are an economical and clean way to heat. Propane is typically more expensive than natural gas, however it is readily available in most place unlike natural gas.

How Boiler power is measured

Boiler power (also known as BHP) is the measurement of the boiler’s capability to supply steam into a steam engine. It is measured in BTU (British thermal units) and represents the rate of thermal energy needed for the evaporation of 34.5 lb water when the temperature is 212°F per hour.

One BHP is equal to 33475 BTU/hour and it can also be derived from the heat transfer area of the boiler.

Mathematically,

BHP = A / 17

Where BHP = boiler power and A = heat transfer area (measured in ft2).

Firetube vs Watertube Boiler

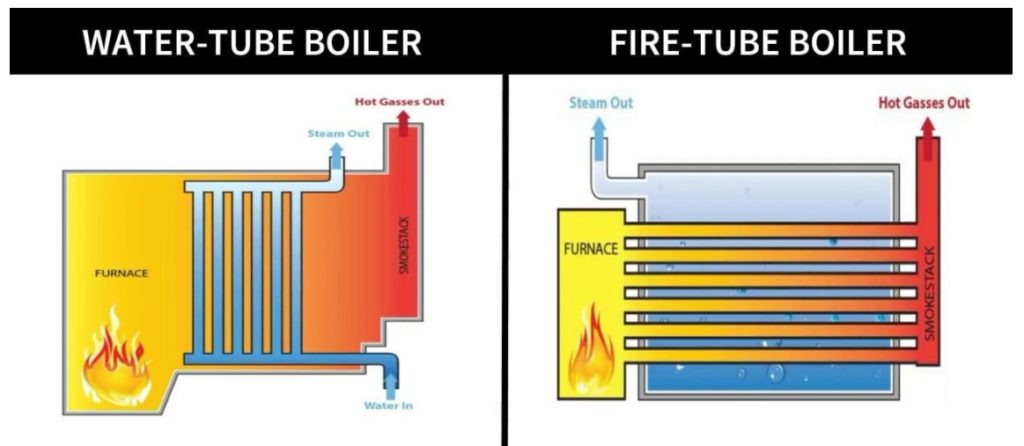

Although these two are the most popular boilers in use today, they are quite opposite of one another in terms of design and operation. While firetube boilers consists of combustion gasses within tubes which are then surrounded by water, a watertube boiler does the opposite and has water inside the tubes which are surrounded by gasses. Operation of each type and the results they produce are slightly different. Working pressure for the firetube is low compared to that of the watertube. Firetubes tend to be more efficient, have a lower cost of ownership, easier maintenance, and simpler operation. However, watertubes product a higher temperature output, offer a safer more dependable design and boast a faster heat recovery.

Rent or Buy a boiler?

This buying guide would not be complete without addressing this question. A boiler is a large investment, and you should take all the pros cand cons of ownership into account before taking the plunge.

Start by analyzing your needs and the resources that are available to you for a boiler system. Although renting may allow you to pay less upfront, the ongoing costs may wind up exceeding the cost of buying a boiler outright.

If you need steam power for a temporary project, it may be best to rent a mobile boiler that is delivered to your project site and removed when you are finished.

If you purchase a boiler, you will inevitably be required to perform routine maintenance, which also means ongoing costs. Whereas, some boiler rental services include free maintenance, or it is an added fee on top of the rental fee.

Unfortunately, there’s no definitive answer on which option is best. It depends on a variety of factors you should heavily consider, including price, usage, length of time you need the boiler, contractual agreements and so on.

Boiler Accessories

Some boilers may come with added accessories or components that are mounted on various sections of the machine to ensure it continues to run with maximum efficiency. These can include the feed pump, injector, economizer, super-heater, and air preheater.

The feed pump and injector are somewhat similar. The feed pump is at the center of delivering the water to the boiler, while the injector does the same thing under pressure. Economizer uses flue gas to heat the feed water. The superheater raises the temperature while keeping the pressure stable, and the air pre-heater is used in a stationary boiler.

Boiler Safety

Ensuring boiler safety is essential since they can be dangerous when poorly maintained or supervised.

There have been reports of explosions but preventing them is fairly easy. Low water conditions are typically to blame. Low-water trip switches, safety devices intended to cut off the fuel supply if the system detects low water levels, should be checked on a regular basis. Note, older boilers may not have such trip switches.

Other precautions include:

- Keeping the area around your boiler clean and free of debris and any flammable materials.

- Frequent inspections for leaks, cracked surfaces, bulges, and corrosion.

Uses for Boilers

Boilers are used in a wide range of industries, including but not limited to the following:

- Electricity generation

- Sterilization, warming, etc. in healthcare facilities

- Textile manufacturing

- Breweries & distilleries

- Automotive manufacturing

- Everyday heating in residential and commercial facilities

- Food & beverage manufacturing facilities

- Commercial laundry facilities

What Size Boiler do You Need?

Boilers come in a range of sizes and selecting the appropriate size largely depends on the amount of heat you need to generate.

In terms of heating a building, you must determine the appropriate BTU. This is the figure that represents the amount of energy needed to increase the temperature of 1 pound of water by 1 degree in 1 hour. Every building will have its own unique BTU requirement based on size, external climate, location, etc. For example, if you’re reviewing a boiler with a rating of 80,000 BTUh, you can assume that its gross output is 80,000 BTUs, or 80 MBH (one MBH = 1,000 BTUh).

Tips for Finding Boilers on Surplus Record

If this guide has proven helpful, you’re probably ready to start looking for boilers to purchase! Once you’ve narrowed down the type of boiler you’ll need, searching our directory is the easy part. With our newly redesigned website, finding the equipment you need has become simpler than ever. You can perform a general search by using the search bar at the top of our website. Simply type in “boilers” and you’re off!

Manufacturers include Cleaver-Brooks, Superior, York-Shipley, Victory Energy and more.

We also work with several dealers who specialize in boilers of various types. You can also find dealers in your area or by name who specialize in boilers.