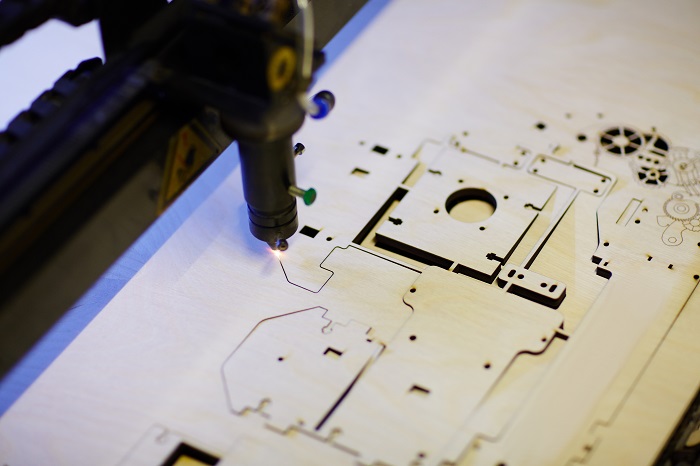

A CNC (Computer Numerical Control) laser cutter is a machine that uses a high-powered laser beam to cut and shape various materials such as metal, wood, plastic, and others. The machine is controlled by a computer program that directs the laser to cut along specific paths, creating highly precise and complex designs. CNC laser cutters are widely used in manufacturing, prototyping, and fabrication industries for their accuracy, speed, and versatility. They are capable of cutting intricate designs and shapes with high levels of detail, making them a popular choice for a wide range of applications.

The development of CNC technology and laser cutting can be traced back to the 1960s and 1970s. In the early days, lasers were used primarily for welding and drilling applications. However, it was soon discovered that they could also be used for cutting a variety of materials, including metal, plastic, and wood.

In the late 1970s, the first CNC laser cutting machines were developed, which allowed for more precise and efficient cutting. Over the years, advancements in technology led to the development of more powerful lasers, better computer control systems, and more sophisticated software.

By the 1990s, CNC laser cutting had become a widely used technology in manufacturing and fabrication industries. Today, CNC laser cutters are capable of cutting with high precision, speed, and accuracy, making them an essential tool for a wide range of applications in various industries.

In this buying guide, we’ll discuss the most popular types of CNC laser cutters, compare their benefits and drawbacks, discuss what to look for when purchasing them, and detail end uses for industrial CNC laser cutters.

Popular Types of CNC Laser Cutters

Potential purchasers can find a CNC laser cutter for wood, glass, metal, leather, stone, acrylic, and many more materials. However, all sorts of CNC lasers, including industrial options all the way to home laser cutter machines, aren’t typically categorized according to their end uses. Instead, they’re listing by their laser type, of which there are three: CO2, fiber, and crystal.

- CO2 laser cutters use a carbon dioxide (CO2) laser to cut and engrave materials. The CO2 laser is created by exciting CO2 gas with an electrical discharge, which produces a high-powered beam of infrared light. The laser beam is then focused through a lens, which directs it onto the material being cut or engraved. CO2 laser cutters are particularly effective at cutting and engraving non-metallic materials, such as wood, acrylic, leather, and paper. They are capable of producing highly precise and intricate cuts with clean edges and minimal waste. CO2 laser cutters are also known for their speed, as they can cut through materials quickly and efficiently. Additionally, they are also commonly used in educational settings, as they are a popular tool for teaching design and fabrication skills.

- Crystal laser cutters, also known as solid-state laser cutters, are a type of CNC laser cutter that uses a solid-state laser to cut and engrave materials. Instead of using a gas like CO2 lasers, solid-state lasers use a crystal or glass material, such as neodymium-doped yttrium aluminum garnet (Nd:YAG), as the laser medium. When the laser is activated, it excites the atoms in the crystal, causing them to emit photons of light at a specific wavelength. This laser beam is then directed onto the material being cut or engraved. Solid-state laser cutters are particularly effective at cutting and engraving metals and other hard materials, such as ceramics and glass. They are capable of producing highly precise cuts with minimal distortion or heat damage to the material.

- The final and newest option is fiber laser cutters. These cutters use a fiber laser to cut and engrave materials. A fiber laser is created by passing an electrical current through a fiber-optic cable, which stimulates the laser medium, typically a rare-earth element such as erbium or ytterbium. The laser beam produced by a fiber laser is highly concentrated and focused, allowing for precise cutting of materials. Fiber lasers are particularly effective at cutting and engraving metals, such as steel, aluminum, and copper, as well as other materials like plastics and ceramics. Fiber laser cutters are known for their speed, efficiency, and low maintenance requirements. They are capable of cutting thicker materials than CO2 lasers, and their high-power density allows for faster cutting speeds with minimal heat distortion. Additionally, fiber lasers are more energy-efficient than other types of lasers, making them an environmentally friendly option.

CO2 vs Crystal vs Fiber

CO2 lasers are best suited for cutting and engraving non-metallic materials such as wood, acrylic, leather, and paper. They are popular for their versatility, affordability, and ease of use. CO2 lasers are also known for their high-quality cuts and ability to produce intricate designs. However, they are not as effective at cutting or engraving metals, and their cutting speeds are generally slower than fiber lasers.

Crystal lasers are particularly effective at cutting and engraving metals and harder materials such as ceramics and glass. They produce a high-power beam that can cut through thicker materials with precision and speed. Crystal lasers also have a longer lifespan and require less maintenance than CO2 lasers. However, they are more expensive than CO2 lasers and have limitations when it comes to cutting non-metallic materials.

Fiber lasers are known for their high cutting speeds and precision, making them the preferred choice for cutting and engraving metals such as steel, aluminum, and copper. They are also energy-efficient and require minimal maintenance. However, fiber lasers are not as effective at cutting non-metallic materials as CO2 lasers, and they are generally more costly than CO2 lasers.

Overall, the choice of which type of laser cutter to use depends on the specific needs of the application. CO2 lasers are a great option for cutting and engraving non-metallic materials, while crystal lasers are best for cutting hard materials like metals, ceramics, and glass. Fiber lasers are ideal for high-speed, high-precision cutting of metals, but may not be the best choice for cutting non-metallic materials. Ultimately, understanding the strengths and limitations of each type of laser cutter is important in selecting the right tool for the job.

What to Look for When Buying CNC Laser Cutters

Looking for new or used CNC laser cutters for sale involves a number of potential pitfalls. Making a poor selection for a given end-use scenario can cost a business a lot in terms of lost productivity, operational expenses, and opportunity cost. When looking for the best laser cutter for small business or industrial contexts, consider the following:

- Wattage. CNC lasers with power ratings of 1000 watts (1kW) and above are usually considered industrial-grade machines. They are capable of handling heavy-duty operations and high-volume production. However, as the power increases, so do the capabilities and potential applications of these machines. Here’s a general breakdown for each category:

- 1000-Watt Laser Cutter. A 1kW laser cutter is a versatile machine that can handle a variety of materials with precision. It can comfortably cut through materials such as stainless steel and aluminum up to 8-10mm thickness and may handle thicker materials under optimal conditions. This makes it suitable for many manufacturing contexts, including small and medium-sized businesses.

- 2000-Watt Laser Cutter. At 2kW, the laser cutter can handle thicker materials, typically up to around 15mm for metals like stainless steel, while maintaining speed and precision. The higher power allows it to cut faster, increasing productivity.

- 3000-Watt Laser Cutter. A 3kW laser cutter will be able to cut even thicker materials, potentially up to around 20mm for stainless steel. At this power level, the machine is also capable of maintaining a faster cutting speed even on thicker materials.

- 4000-Watt Laser Cutter. A 4kW laser cutter is an industrial-grade machine capable of cutting through very thick materials, potentially up to 25mm for metals like stainless steel. These machines are designed for high-volume, heavy-duty applications.

- 5000-Watt Laser Cutter. A 5kW laser cutter is a high-powered machine designed for maximum productivity and versatility. It can cut through very thick materials (possibly 25mm or more) rapidly and precisely. This power level is often found in large-scale manufacturing operations, where high speed and the ability to handle a broad range of materials are crucial.

- Type of Radiation Source and Its Power. Previous sections have already discussed the three main types of CNC lasers and their best use cases. Power is also equally important when buying CNC machines with higher wattages equaling greater cutting capacity.

- Service Life. Failing to account for the estimated effective operating life of a laser cutter and its service requirements can mean that a seemingly inexpensive machine will become very expensive over time.

- Cost of Maintenance. No matter the expected life of a machine or its quality, every CNC laser cutter will require regular maintenance, and you will need to account for it prior to purchasing.

- Delivery and Installation. Is delivery included? What about installation? If not, do you have the requisite transportation, capital and/or installation expertise necessary to complete both tasks?

- Price. Is the cost of the machine in line with other options in similar condition?

- Warranty. The inclusion of a warranty can make a purchase much more attractive. However, check to see if the warranty is provided by the manufacturer or the seller and confirm exactly what it covers.

- Post-Sale Technical Support. CNC laser cutters are complex tools and often require manufacturer support for significant periods after purchase. This can prove challenging if a manufacturer has merged with another company, is no longer in business, or has limited technical service offerings.

Applications & Uses

Though many discussions about CNC laser cutters tend to focus on metal cutting, these machines have several other applications, including:

- Manufacturing: CNC laser cutters are widely used in the manufacturing industry for cutting and shaping a variety of materials, including metals, plastics, and composites. They are used to produce parts, prototypes, and finished products for a range of applications.

- Fabrication: CNC laser cutters are used in the fabrication industry for cutting and shaping metal components. They are used to create everything from decorative elements to structural components for buildings and vehicles.

- Signage: CNC laser cutters are used to create custom signs for businesses and organizations. They are capable of cutting intricate shapes and designs, and can be used to create illuminated signs, channel letters, and other types of signage.

- Woodworking: CNC laser cutters are used in woodworking for cutting and engraving wood components. They are used to create everything from furniture to decorative pieces and can produce highly detailed designs and patterns.

- Textiles: CNC laser cutters are used in the textile industry for cutting and engraving fabrics. They are used to create custom designs, logos, and patterns on a range of materials, including cotton, silk, and synthetic fabrics.

- Medical: CNC laser cutters are used in the medical industry for cutting and shaping medical devices, such as stents and implants. They are also used in surgical procedures, such as laser eye surgery and dental procedures.

- Art and Design: CNC laser cutters are used in the art and design industry for creating custom designs and artwork. They can be used to cut and engrave a range of materials, including wood, acrylic, and paper.

These are just a few examples of the many applications and uses of CNC laser cutters. With their precision, speed, and versatility, they are used in a wide range of industries and applications.

Accessories for CNC Laser Cutters

There are various accessories that can be used with CNC laser cutters to enhance their capabilities and improve the quality of the cuts. A few examples include:

- Rotary Attachments: Rotary attachments allow CNC laser cutters to engrave cylindrical objects such as cups, bottles, and tubes. The attachment rotates the object while the laser is engraving, ensuring an even and accurate result.

- Exhaust Systems: Exhaust systems are used to remove fumes and particles generated during laser cutting. They help to improve air quality and maintain a safe working environment.

- Chiller Units: Chiller units are used to cool the laser and prevent it from overheating during extended cutting periods. They help to ensure consistent cutting quality and prevent damage to the laser.

- Lens Kits: Lens kits include a range of lenses with different focal lengths, allowing for greater flexibility in the types of cuts that can be made. Different lenses are used for cutting thick or thin materials, or for engraving different types of materials.

- Honeycomb Cutting Table: Honeycomb cutting tables provide a flat and level surface for cutting materials, while also allowing for efficient removal of waste materials and reducing the risk of material damage.

- Air Assist Systems: Air assist systems blow compressed air onto the material being cut, which helps to remove debris and prevent burning or melting. They can also help to improve cutting quality and reduce the need for post-cut cleaning.

These are just a few examples of the accessories that can be used with CNC laser cutters to improve their capabilities and the quality of the cuts. The type of accessories needed will depend on the specific application and the materials being cut.

Tips for Finding and Buying a CNC Laser Cutter

CNC laser cutters represent significant capital investments, and businesses should only purchase such complex pieces of equipment from trusted sellers. Surplus Record has extensive experience in connecting buyers with quality used equipment from reputable sellers. Once you’ve determined the type of laser cutter you require for your organization’s end use, you can easily search our site to see what’s for sale. Sort by manufacturer, model, location, and various keywords.

Top manufacturers for CNC laser cutters include: Amada, Bystronic, Mazak, Blm Adige, and Trumpf

Trust the Best CNC Laser Cutter Dealer Around

Surplus Record has a passion to help businesses sell surplus and unwanted equipment. Since the early 20th century, Surplus Record has supported machinery dealers and aided thousands of dealers and individual sellers in connecting with end-user consumers and various businesses.

Surplus Record’s comprehensive database of surplus, new, and used equipment is a great place to start if you’re currently in the market for new tools or machinery.