Blast Cleaning and Shot Peening processes are not modern metalworking processes, although the technology of the 21st century has definitely helped progress the advancement of this equipment. Blast cleaning equipment (or sand blasting) has existed as early as the 1800s where it was first invented by a soldier of the United States called Benjamin Chew Tilghman. The method known as “shot peening” has existed for even longer. This method was used to forge swords and other weapons and tools in the Bronze Age period. The equipment we use today for the processes of blast cleaning and shot peening are far more developed than they were from these earlier times in history.

In this article we are going to present a buyer’s guide for blast cleaning and shot peening equipment. We shall discuss the basics of how this type of equipment works, provide some tips and tricks to reflect upon along with what to look for when searching for the best used blast equipment and shot peening equipment for sale at Surplus Record.

Most Popular Types

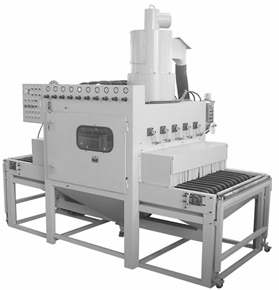

The two most popular and common types of Blast Cleaning & Shot Peening Equipment are the Booth, Conveyor, Table Blast and the Tumble Blast variants. These can be found pictured below for reference.

All of these different versions of blast cleaning and shot peening equipment serve the same purpose, however, they are more specialized in their own ways at their specific task at hand.

The Booth

When discussing blast cleaning and shot peening equipment, the booth setup is one of the most practical. It completely confines the sand particles which are used to either clean or peen your steel workpiece. This not only adds the benefit of less clean up after work, but also eliminates the health risks associated with inhalation of the sand particles. Booths can be used for small to very large sized workpieces. As with all cleaning and shot peening equipment, depending on the size of the booth, it can be used upon any type of metal to great effect. Have a look through our available range of used blast cleaner booths for sale.

The Conveyor

A conveyor functions exactly the way its name suggests. The workpiece is placed on a conveyor belt which continuously feeds through the machine’s blasting booth. Conveyor set ups are excellent for evenly cleaning or peening a workpiece, particularly longer lengths of steel. They are highly productive pieces of equipment as the process is automated and the conveyor’s processing speed is adjustable to suit your own specific job requirements. For further information, have a scroll through our available range of used conveyors for sale.

The Table Blast

Inside the machine chamber can be found a circular blasting turntable and several more “satellite” tables attached to the turntables surface. The workpieces are placed on the satellite tables for cleaning or peening. As blasting commences this turntable rotates at preadjusted speeds and the satellite tables attached to the turntable are rotated one by one under the abrasive. The table blast is well suited to jobs that are fragile and require production-based precision. Have a look through our available range of used table blast cleaners and shot peeners for sale.

The Tumble Blast

Consistency and productivity are the benefit of using the tumble blast variant of blast cleaners and shot peeners. Multiple workpieces are placed inside the chamber of the machine and are forced to “tumble” on a belt. It is an aggressive process therefore its only suitable for steel which is tolerant of this. The final result is a mass production with near perfect finishes throughout all of the workpieces. Have a look through our available range of used tumble blast cleaners and shot peeners for sale.

Uses and Applications

Blast cleaning and shot peening are both forms of abrasive blasting, but where the difference is found is in their purpose, not the equipment itself which is actually the same. Blast cleaning, via the application of a projectile abrasive (commonly sand), removes paint or other unwanted surface coatings. The purpose here is literally to clean the surface of the steel. Peening on the other hand, also utilizes a projectile abrasive however, the intention here is to remove residual stress within the metal which, left untreated, can cause cracking. By “compacting” the steel down through the application of abrasive pressure, the tension within the steel which would cause the cracking, is released.

What to Look for When Buying Blast Cleaning & Shot Peening Equipment?

Your Work Purpose

It is likely that you now understand the different uses and benefits of each of the 4 different types of machines we have for sale at Surplus Record. By understanding which machine is more suited to your specific task at hand, you will be much more likely to select an appropriate machine for your workforce.

Inspecting for Damage

A blasting or peening piece of equipment with damage is normal due to the nature of the work. However, excessive damage to the point where the equipment is faulty or nonoperational should not be for sale. We recommend inspecting your equipment well to make sure it’s at an acceptable standard and test it before purchase if possible. Used shot blast equipment for sale will always at minimal have minor wear and tear

Useful Accessories

There is a variety of useful accessories available to purchase alongside your used shot peening and blast cleaning equipment. These could include heavy duty fans and lighting equipment, respiratory equipment such as suits, masks and helmets and blow guns for cleaning.

Surplus Record: Tips and Tricks

When searching for used blast cleaning and shot peening equipment for sale on our platform, we have attached some of our best tips and tricks to make finding the best machine to buy a little bit easier.

- Make use of our Location Settings: At the top of the page when on the list for either blast cleaners or shot peening equipment, enter your desired location and you’ll be taken directly to what we have available in your area.

- Looking for an Auction: On the listing page, select the blue checkbox on your right which says “Auction” to be taken to our available blast cleaners or shot peening equipment for sale on auction.

- On a Budget: Select the toggle “Sort by Relevance” and then click “Price low to high” to view our cheapest to more expensive used blast cleaners and shot peening equipment sale.

- Don’t forget the Search Bar: Already know what you are looking for? Utilize our search tab at the top of your page to find specific listings out of our hundreds available.

Quick Access: Blast Cleaning & Shot Peening Equipment Dealers

- Bayliss Machine Welding Co | Alabama

- Cardinal Parts Equipment | Indiana

- Blast Wash Systems | New York

- Arrow Industrial Equipment | Texas

At Surplus Record, we understand that the process of searching for the best used blast cleaning and shot peening equipment for sale can be quite daunting. Our advice is to take your time, do your research and use this buyer guide and the process of finding the best blast cleaning and shot peening equipment to buy will be straightforward. Almost easy!

Our top 3 manufactures available on Surplus Record for Booth options include: Blast It All, Empire, Guyson, and Trinco with a great variety of other manufacturers listed as well.

3 of our top options for Conveyor manufacturers include: Goff, Wheelabrator, and Pangborn as well as many more.

Our top 3 manufactures for the Table Blast option include: Wheelabrator, Goff, Pangborn, and Cardinal along with a large variety of other manufacturers.

Finally, our top 3 manufactures for the Tumble Blast option include: Wheelabrator, Goff, Pangborn, and Cardinal with a variety of other manufacturers listed too.